How to reduce your water footprint when making potato chips

Water is one of our most precious assets, and we are not making good use of it. It has been estimated that by 2030, half the population will face water scarcity problems due to climate change, water pollution and a growing population. The manufacturing industry consumes between 20-40% of all available freshwater, so the question arises: what are manufacturers doing to reduce water consumption in the industry?

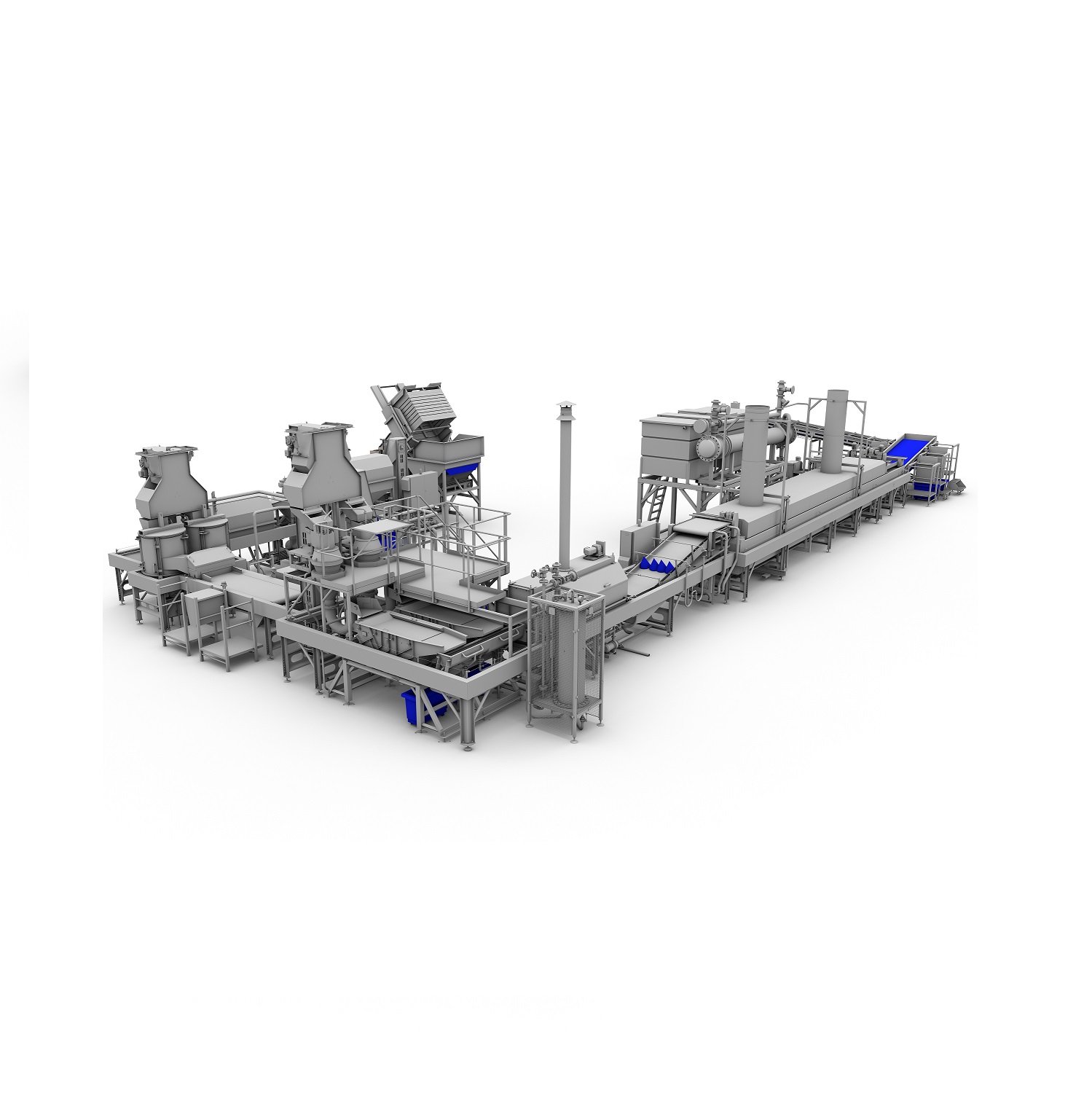

We broached the subject with Valeria Lucinschi, from Kuipers Food Processing Machinery to learn how this works in potato chip production.

Potato chip producers use on average eight cubic meters of water per hour. Wait, what?

Yes, you heard it right. On an industrial scale, producers consume 8 m3 of water per hour when making potato chips. Water is used in almost all preparation steps and is essential when preparing potato slices before frying. And not just for cleaning purposes as you may be thinking. After being washed for the first time and peeled, the potatoes are sliced and rewashed to remove some of the starch. If this step is not done well, it can greatly affect the quality of the end product as well as the frying process. Starch can block the evaporation of moisture from the potato when frying by leading to a browning reaction. If this happens, forget your crispy and golden-colored chips.

It is recommended to have a good slice washing system to wash the potatoes very carefully, mainly when the blanching is not applied. Although producers may skip this step, especially when potatoes are fresh, it is generally advised to blanch to ensure a smoother deep frying process. If blanching is applied, slices must pass a final washing and drying to remove any adherent particles and water before frying.

Reduce water consumption in your potato chip production line by 60%

Back to our question now. What are producers doing to reduce these eight cubic meters of water?

Valeria explained that Kuipers has reduced water consumption in the potato chip production line by recycling water from one stage to another. This can be done thanks to a water treatment system that only uses fresh water at one stage of production – to be clear when potatoes are on the spreading belt that blows water to wash them just before frying. From here, the system recycles the water that goes back to the previous stages. The water is filtered through a cyclone system that cleans it and removes the starch so it can be reused again. The Kuipers water system technology uses up to 60% less water than conventional systems, meaning they use 4 m3 per hour on average.