Cracking the code of fried peanuts: how to produce the tasty snack

Either coated, battered or enjoyed just as they are, peanuts are popular in different parts of the world as a good companion to a cold beer when watching your favorite series or sports. In the United States, for instance, the consumption of peanuts in 2021 was a record for the second year in a row, with 3,5kg of peanuts consumed by person. To get the best taste and consistency for all these consumers, the advice is to deep fry the nuts. While we all know that too many fried products can be bad for our health, we dare you to find someone who resists the charms of a well-fried peanut. But why is it so popular and how can you make even better peanuts?

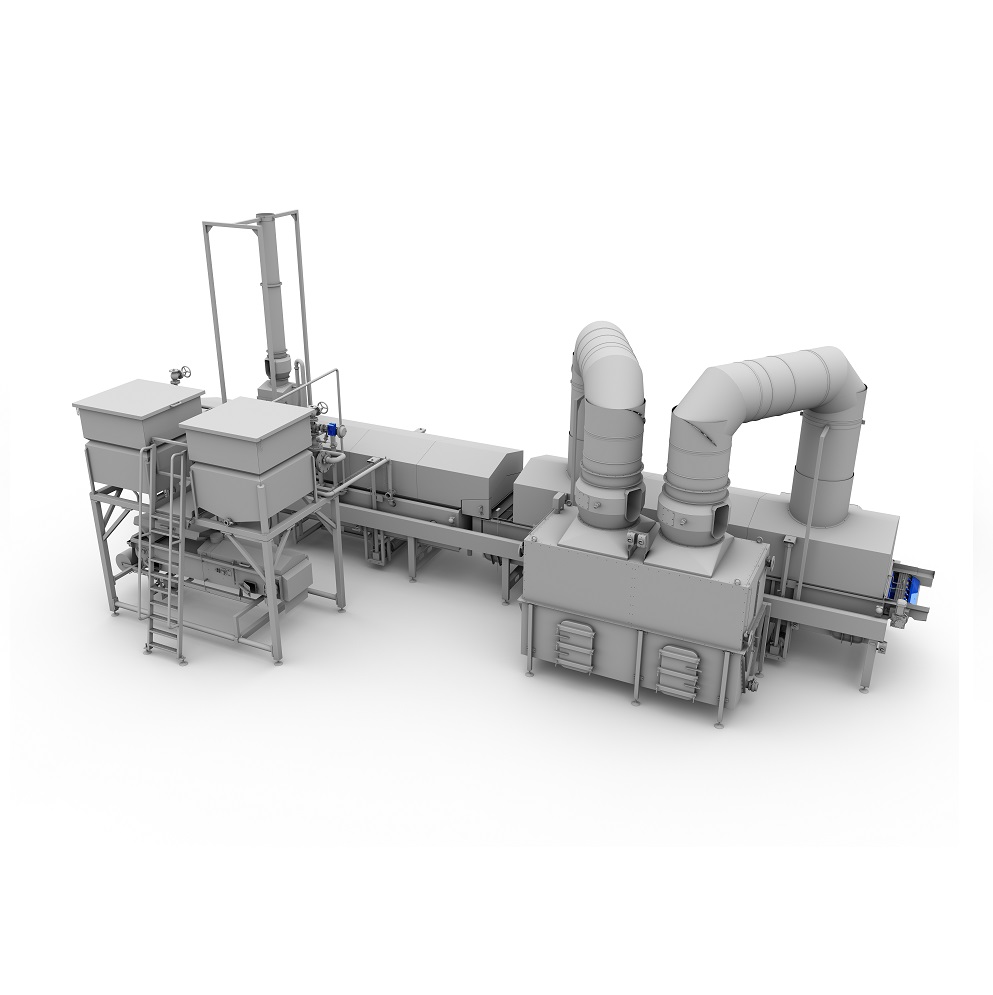

Making peanuts: deep-frying for a safe and tasty product

Peanuts have a low oil absorption, and this can make their production challenging. Maintaining an efficient industrial frying process, however, helps snack manufacturers achieve the right taste of the nut. Frying is also a quick and effective way of removing moisture for prolonged shelf life. Moreover, some studies suggest that heat treatment decreases levels of aflatoxins, which can harm human health. Ideally, the frying occurs with the oil from the nut being used. But as the investment in peanut oil can be expensive, producers opt for alternatives. Sunflower oil is the most common one.

To make peanuts more efficiently, regardless of the oil type you use, mind how you use it. Using a lower amount of oil and keeping it clean for longer periods helps optimize costs of ingredients, while also controlling the amount of Free Fatty Acids of the nuts – which in general cannot surpass 2%. FFAs are lipid species that contribute to insulin resistance and a higher risk of cardiovascular diseases. A smaller amount of them helps make a healthier product.

Keeping the oil good: how to maintain oil quality and save frying costs

Linked to the amount of oil is the turnover time. This is the rate at which the total frying oil volume is refreshed within the system. The shorter the turnover time, the better – it helps prevent the oil degradation and increases product shelf life. It also ensures that you’ll deep fry the peanuts with good quality oil, which you won’t need to change often. Changing oil means stopping production, which takes time, energy, and resources. “When frying peanuts, make sure that the oil you use is good for as long as possible. This way you can significantly reduce your costs”, highlights Valeria Lucinschi, Head of Sales and Business Development at Kuipers.

“With an innovative fryer design you can decrease by up to 40% the total volume of oil used within the system. This combined with an efficient filtration system and temperature control will help you achieve better turnover times – around one-third shorter than usual”, she explains. To produce nuts in a better and more cost-efficient way, make sure your oil turnover rate is low and guarantee its quality throughout the process. Mind the standards of FFAs while still providing the unmistakable taste and feel of the product.