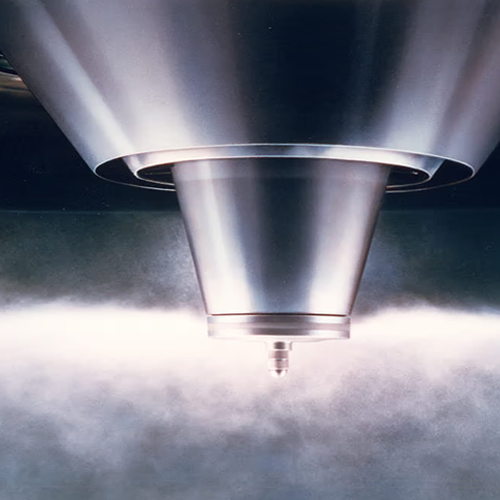

Spray dryer absorber for flue gas desulphurization

Efficiently transform gaseous pollutants into stable byproducts while meeting stringent environmental regulations with this cutting-edge emissions control technology.

Removes Acidic Pollutants and Controls Emissions

The Spray Dryer Absorber (SDA) system from GEA efficiently manages flue gas desulphurization and emission control in power plants, waste incinerators, and industrial installations. Utilizing a semi-dry process with a Rotary Atomizer, it atomizes slaked lime to remove SO2, HCl, and other acidic gases. This method results in dry, stabilized end-products like calcium sulfate and fly ash, suitable for construction use. The SDA system ensures high removal efficiencies with low energy and water consumption, even tolerating low-quality water inputs. With over 200 installations globally, it delivers reliable operation and meets stringent environmental standards. Automated controls facilitate integration, and the system’s durable materials minimize maintenance needs while offering customizable configurations for specific operational requirements.

Benefits

- Achieves high acid-gas removal efficiencies, ensuring compliance with strict emission regulations.

- Operates with low capital, operating, and maintenance costs, enhancing cost-effectiveness.

- Utilizes low-quality water, reducing resource dependency and operational costs.

- Provides high plant availability, minimizing operational disruptions.

- Generates no wastewater, supporting zero liquid discharge and environmental compliance.

- Applications

- Particulate matter control, Waste incineration, Emission control systems, Acid gas removal, Sinter plants, Industrial installations, Air pollution control, Flue gas desulphurization, Power generation

- End products

- Powdered activated carbon dust, Dry calcium sulfate, Fly ash, Dry absorbent powder, Construction-grade calcium compounds, Stabilized fly ash

- Steps before

- Flue Gas Generation, Lime Preparation

- Steps after

- Dust Collection, End Product Storage, Recycling, Emission Monitoring

- Input ingredients

- hot untreated flue gas, acidic pollutants, heavy metals, dust, SO2, SO3, HCl, Hg, dioxins, slaked lime Ca(OH)2, burned lime CaO

- Output ingredients

- clean flue gas, stable dry powdery product, fly ash, various calcium compounds, CaSO3, CaSO4

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Acid-Gas Removal Efficiency

- High

- Power Consumption

- Low

- Water Consumption

- Low

- Absorbent Type

- Slaked lime (Ca(OH)2)

- Flue Gas Flow Rate

- up to 2, 000, 000 Nm3/h

- Atomizer Speed

- 10, 000 rpm

- End Product State

- Dry Powder

- Absorbent Reaction Time

- Rapid

- Capacity

- Installed at over 25, 000 MWe capacity

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cleanability

- Yes

- Machine Footprint

- Varies based on gas volume

- Chamber Shape

- Cylindrical with coned bottom

- Material

- Mild steel, stainless steel

- Discharge Method

- Outlet duct located at the coned bottom

- Atomizer Type

- Rotary Atomizer

- Atomizer Wheel

- Less than 50 microns droplet size

- Absorber Capacity

- More than 2, 000, 000 Nm³/h in one chamber

- Absorber Chamber Size

- Depends on flue gas volume and properties

- Control panel type

- PLC-controlled

- Absorbent integration

- Slaked lime or onsite prepared

- Peak control system

- Yes

- Activated carbon injection

- Optional

- Recycle system

- Available