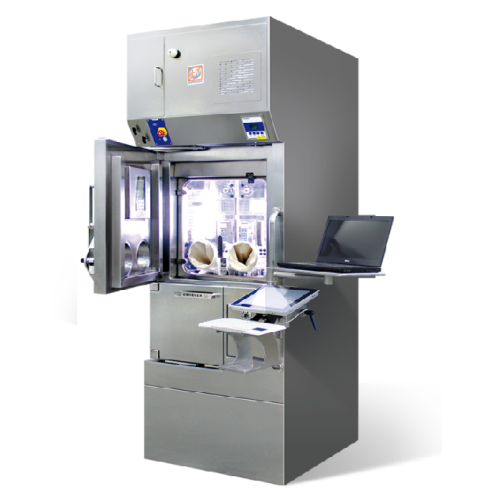

Shielded isolator for radiopharmaceutical syringe dispensing

Streamline your radiopharmaceutical production with a compact, shielded isolator designed for precise syringe dispensing and efficient handling of Gallium-68 solutions under sterile conditions.

Dispenses and Calibrates Gallium-68 Radiopharmaceutical Doses

The THECLA Shielded Isolator from Comecer is meticulously designed to address the stringent requirements of dispensing Gallium-68 radiopharmaceuticals under sterile conditions. This innovative isolator features a semi-automatic dispensing system for syringes, ensuring precision and safety in radiopharmaceutical production. Equipped with a Comecer IBC Dose Calibrator, it accurately measures and calibrates doses within a range of up to 2 Ci. The isolator operates with laminar airflow to maintain Class A and B air quality, essential for producing sterile 68Ga-labeled compounds like PSMA ligands and DOTATATE. Compact in design, the THECLA integrates seamlessly into existing production lines, even in confined spaces. It employs 50 mm lead shielding and HEPA H14 filtration to guarantee operational safety and contamination control. Additionally, the system’s stainless steel construction provides durability and ease of decontamination, while the option to install a Geiger-Muller probe ensures radiation levels are continuously monitored. Fully compliant with cGMP guidelines, this isolator offers pharmaceutical manufacturers, radiopharmaceutical producers, and hospital pharmacies a dependable solution for efficient and safe radiopharmaceutical dispensing.

Benefits

- Ensures precise and safe radiopharmaceutical dispensing with integrated dose calibration.

- Maintains sterility with laminar airflow and cGMP-compliant air quality control.

- Fits into tight spaces, maximizing available laboratory space without compromising functionality.

- Provides radiation protection with extensive lead shielding, ensuring operator safety.

- Offers seamless integration into existing systems, minimizing disruption and setup time.

- Applications

- Syringes, Sterile products, Radiopharmaceuticals, Gallium-68

- End products

- 68ga-dotatate, 68ga-labeled psma ligands, 68ga-pet/ct tracers, 68ga-dota-noc, Sterile 68ga radiopharmaceutical doses, 68ga-dotanoc

- Steps before

- Material Introduction, Syringe Preparation

- Steps after

- Dose Calibration, Final Product Extraction, Sterilization

- Input ingredients

- radiopharmaceuticals, 68Ge/68Ga generator, material for dispensing

- Output ingredients

- dispensed syringes, final product in shielded containers

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Compliance

- cGMP

- Air Quality

- Class A, Class B (EEC-cGMP)

- Automation

- Semi-automatic dispensing

- Shielding

- 50 mm lead

- Laminar Flow

- HEPA H14 filtration

- Material

- 304, 316L AISI stainless steel

- Measurement Range of Dose Calibrator

- up to 2 Ci

- Temperature,Humidity Monitoring

- Yes

- Filtration system

- Active carbon outlet

- Power Supply

- Protected, operator controlled

- Radioactivity Detection

- Geiger-Muller probe option

- Shielded front door

- With hand access

- Pressure control

- Constant negative or positive pressure

- Material transfer method

- Semi-automatic dispensing system

- Final product extraction

- In shielded container

- Installation flexibility

- Compact size for confined spaces

- Filtration system

- Laminar flow with HEPA H14 filters

- Air quality compliance

- Class A and Class B (EEC-cGMP)

- Automation level

- Semi-automatic

- Access method

- Hand access

- Biological compatibility

- Yes

- Cleanability

- Easy to decontaminate

- Corrosive resistance (e.g. acids)

- Yes

- GMP Compliance

- Yes

- CE marking

- Yes

- ISO 9001 Certification

- Yes

- ISO 13485 Certification

- Yes

- Machine footprint

- Compact design, suitable for confined spaces

- Material introduction chamber

- Class B “At rest” air quality

- Dispensing chamber

- Class A “At rest” air quality with laminar flow

- Syringe dispensing system

- Semi-automatic

- Material transfer compartment

- Lower compartment with transfer tray

- Shielding

- 50 mm lead shielding

- Chamber material

- 316L AISI stainless steel

- Support structure

- Epoxy-coated carbon steel

- Front coverings material

- 304 AISI stainless steel

- Pressure control

- Negative or Positive (upon request)

- Main chamber shielding

- Hinged front door with hand access

- Internal surface finish

- Mirror-Bright

- Door access

- Glass and hand doors for manipulation

- Installation flexibility

- Positioned in confined spaces

- Maintenance access

- Front wall

- Gas supply line control

- Controlled from the outside