Low-flow vaporizer for precise chemical vapor deposition

Ensure stable and precise vapor control for low-flow applications, enhancing the efficiency and consistency of your continuous vaporization processes.

Delivers Consistent Vapor Concentrations for Low-Flow Applications

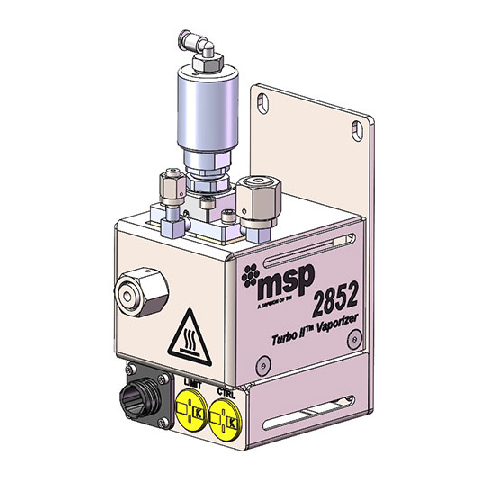

The Low-Flow Turbo II Vaporizer 2852NP, part of the MSP Turbo™ series, is engineered to deliver stable vapor concentrations crucial for semiconductor and chemical industry applications. Designed for low-flow operations, it integrates seamlessly into continuous processing lines, offering flexibility with various liquid flow controllers. The vaporizer employs a robust heater system capable of temperatures ranging from 180°C to 340°C, ensuring precise control over vaporization processes.

With fittings compatible for inert gas and standard pressure operations, the 2852NP adapts to diverse production environments while maintaining a compact form factor (198 mm x 79 mm x 114 mm) and a manageable weight of 2.5 kg. Constructed with corrosion-resistant materials like SS 316, PEEK, and PTFE, it promises durability in demanding chemical contexts. Featuring a liquid shut-off valve, the vaporizer ensures safety and efficiency, ideal for research laboratories and advanced materials producers needing reliable vapor delivery solutions. The unit is engineered to handle a maximum carrier gas flow of 12.0 standard liters per minute and a liquid flow of up to 27 g/min, dependent on the carrier gas and vapor pressures used.

Benefits

- Ensures stable vapor delivery, enhancing process reliability in semiconductor and chemical production.

- Compact design minimizes space requirements in production facilities.

- Reduces maintenance costs with a low-maintenance design and durable construction materials.

- Enables precise temperature control for accurate vaporization, crucial for sensitive applications.

- Supports flexible integration with various liquid flow controllers, increasing adaptability to existing systems.

- Applications

- End products

- Steps before

- Purification, Precursor Mixing, Flow Rate Calibration

- Steps after

- Thin Film Deposition, Coating, CVD Process

- Input ingredients

- carrier gas, inert gas, liquid (TEOS or equivalent), compressed air

- Output ingredients

- vapor, stable vapor concentrations

- Market info

- Dimensions

- 198 mm x 79 mm x 114 mm (7.8 inch x 3.1 inch x 4.5 inch)

- Weight

- 2.5 kg (5.6 lb)

- Fittings - Carrier Gas Inlet

- 1/4 in. VCR female split nut

- Fittings - Liquid Inlet

- 1/8 in. VCR female

- Fittings - Vapor Outlet

- 1/4 in. VCR female split nut

- Fittings - Compressed Air

- 4 mm instant tube fitting

- Wetted Parts

- SS 316, PEEK, PTFE, Elgiloy®, FFKM

- Leak Integrity

- ≤ 1x 10⁻⁸Pa·m³/s Helium

- Heater Power Requirements

- 1208 VAC, 60 Hz, 450 W

- Recommended Carrier Gas

- Inert gas

- Max Carrier Gas Flow

- 12.0 standard liters/min N2@ 50 psig

- Max Liquid Flow

- 27 g/min (TEOS or equivalent)

- System Pressure Limit

- 150 psig

- Compressed Air Pressure

- 90 to 110 psig

- Temperature Range

- 340°C to 180°C

- Temperature Sensor

- 2 type Ƙ thermocouples

- Vapor flow rate

- Low to mid

- Liquid control

- Integrated liquid shut-off valve

- Footprint

- Small

- Temperature control

- 340°C to 180°C

- Automation level

- Compatible with integrated flow control valve systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Carrier Gas Compatibility

- Inert gas

- Dimensions

- 198 mm x 79 mm x 114 mm (7.8 inch x 3.1 inch x 4.5 inch)

- Weight

- 2.5 kg (5.6 lb)

- Fittings

- Carrier Gas Inlet 1/4 in. VCR female split nut, Liquid Inlet 1/8 in. VCR female, Vapor Outlet 1/4 in. VCR female split nut, Compressed Air 4 mm instant tube fitting

- Wetted Parts Material

- SS 316, PEEK, PTFE, Elgiloy®, FFKM

- Compact footprint

- Very small