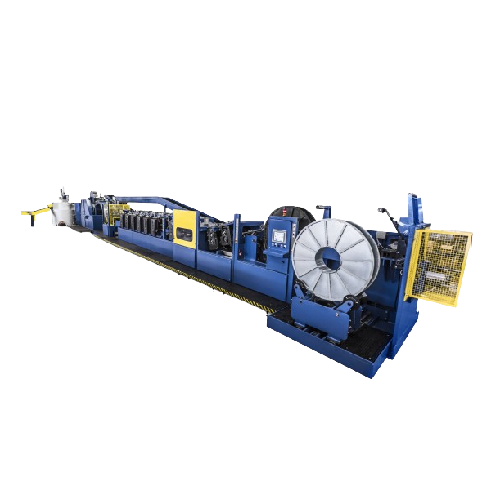

Lead strip manufacturing line

Enhance your battery production efficiency with a complete solution for precise lead strip manufacturing, offering seamless integration into processing departments to streamline operations and improve quality.

Produces Lead Strips for Battery Manufacturing

The LCR Lead Strip Manufacturing Line from Sovema Group is engineered to enhance your battery production capabilities by efficiently producing precision lead strips. This line specializes in a streamlined strip casting and rolling process to ensure high-quality, uniform lead strips essential for battery reliability. Designed for seamless integration into your existing operations, it offers a robust processing capacity tailored for battery manufacturing demands. Automation is a key feature, with PLC-controlled systems that allow for easy monitoring and adjustments. Its energy-efficient operation reduces costs by optimizing motor usage and settings, while material options include durable alloys to withstand the rigors of lead processing. Sovema Group provides engineering support for customization, ensuring the equipment meets your specific production requirements.

Benefits

- Enhances production efficiency with streamlined lead strip casting and rolling.

- Lowers operational costs through energy-efficient motor optimization.

- Integrates seamlessly with existing battery manufacturing lines for improved workflow.

- Minimizes maintenance time with reliable, durable material construction.

- Offers flexible customization to meet specific production needs.

- Applications

- Batteries

- End products

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Working mechanism

- Automated lead processing

- Integrated steps

- Lead extrusion, rolling, and cutting

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC Controlled

- Energy efficiency

- Optimized for low power usage

- Changeover time

- Minimal downtime

- CIP/SIP

- Manual cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Strip Shape and Size

- Lead strip