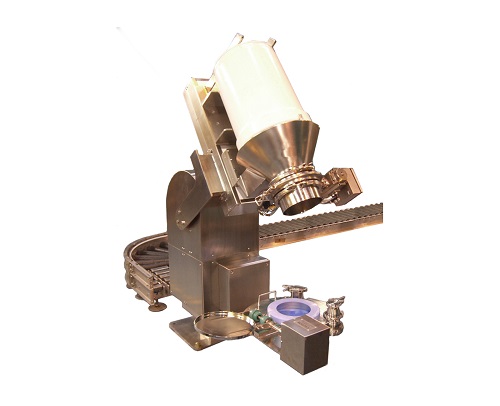

Drum tipper

Many pharmaceutical processes require drums of powders or liquids to be fed from one part of the process to the next. Traditional manual handling can increase operator exposure to potentially hazardous dust, as well as provide incomplete product discharge. An automated tipping system overcomes these problems while being able to handle a large range of drum heights and diameters.

A range of automated tippers for pharmaceutical drums and barrels

The PalPharmaTip range from Palamatic has been specifically developed to provide an ergonomic and easy method of transferring liquids and powders from drums at all stages of pharmaceutical production process.

Suitable for drums up to 350kg in weight, the PalPharmaTip can be constructed in a range of materials from mild steel through to 316 stainless to suit your exact requirements. It’s also available in a range of static and mobile configurations, allowing you to customise it to meet your exact needs.

A full range of movement options are available, including rotation, and all movement is driven either electronically or pneumatically – no hydraulics are used. The drum cradle features a vibration function to aid the complete discharge of sticky compounds.

A wide set of other options are available including loss in weight weighing, conveyor or wheeled dolly fed, and a range of drum clamping options.

Maximum lift and tip heights are set entirely to suit your application, and all PalPharmaTips can be fitted with FDA approved gaskets and seals and also split butterfly valve for high potency transfer applications.

Benefits

- Bespoke automatic drum lift and tip solution designed for your application

- Highest quality construction, including up to 316 stainless where required

- Increased operator safety by remote operation where required

- FDA approved sealing and gaskets

- Dual-handed fail-safe operation