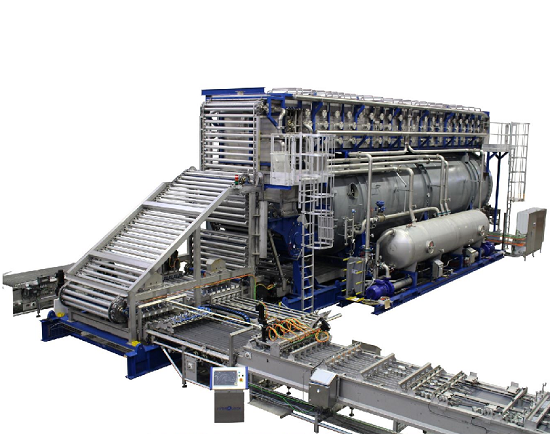

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and quality of products while extending shelf-life. Canned coffee struggles with this the most because coffee is incredibly volatile at high temperatures. It means that coffee starts to chemically breakdown the moment it’s brewed. A continuous rotary sterilizing technology dedicated to medium and large-scale producers of canned coffee can be helpful in extending product drinkability while preserving its organoleptic qualities and colors.

An autoclave, able to handle sensitive printing on the can

The autoclave ACCT series of Hydrolock is a continuous sterilizing unit, dedicated to products packed in tin cans and glass jars in different sizes. Due to this flexibility and the possibility to handle sensitive printing on the can, the ACCT series is an ideal solution for canned coffee producers. After the automatic loading of cans in rotating tubes, the product starts its journey by entering the pre-heating unit (if necessary), the sterilizing unit and the cooling unit which takes place in the autoclave. After leaving the autoclave, products go through an atmospheric cooling unit, after which they are automatically unloaded.

The continuous agitation of products during the heating and cooling stage prevents products from getting burnt. Additionally, it allows for utilization of a high temperature, commonly called HTST – High-Temperature Short Time, for short sterilization time, which enhances product quality. This process also increases line throughput and saves you 35% more on energy savings.

The ACCT series has a pre-heating device that is used for energy recycling. The hot water coming from the cooling process is used for preheating the products before sterilization. During sterilization, products are fully surrounded by steam. This provides a homogenous heat distribution with the aid of an efficient hydraulic fan power system to avoid burning and over-cooking the products.

The series can run different sizes and different materials within the same machine depending on the packaging. The speed range goes upward from 100 cans per minute to 690 cans per minute. This depends on the product’s best sterilization time, packaging, and other critical parameters. The ACCT series is made out of stainless steel guaranteeing longevity, easy maintenance, and cleaning.

Benefits

- Flexible packaging

- User-friendly operation

- Designed for medium and large-scale production