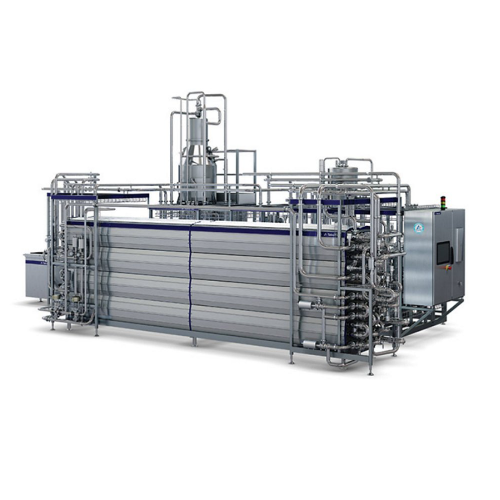

Indirect Uht processing for dairy products

Producing shelf-stable dairy products requires effective and efficient ultra-high temperature (UHT) treatment. Traditional methods may result in suboptimal preservation of flavor and nutrients, and can waste substantial energy and resources.

Provides continuous Uht heat treatment

The Tetra Pak® Indirect UHT unit DE is a specialized processing unit designed for continuous ultra-high temperature treatment of dairy products under aseptic conditions. Utilizing a tubular or plate heat exchanger for indirect heating, the unit achieves a long shelf life at ambient temperatures. One of its standout features is the product-to-product regeneration system, providing up to 92% heat recovery and reducing steam consumption to just 20 kg per 1,000 kg of product. Fouling control mechanisms ensure the unit can operate for up to 40 hours continuously with good quality white milk. This system also includes the IntelliCIP™ 2.0 for optimized cleaning processes and minimized downtime. The balance tank’s bottom-filling design minimizes product loss, while additional functionalities like automatic damper and hibernation mode further enhance its efficiency and operational lifespan. Tetra Pak, the supplier, ensures the unit fits well within the dairy industry for products such as milk, flavored milk, and yoghurt drinks, as well as non-dairy low acid products like soy milk and various beverages.

Benefits

- High heat recovery rate up to 92%

- Long continuous operation periods up to 40 hours

- Minimized product loss with bottom-filling balance tank

- Optimized cleaning with IntelliCIP™ 2.0

- Reduced energy consumption with hibernation mode