Water bath formation system

Enhance battery performance with precise temperature control, ensuring consistent formation and increased longevity for lead-acid, automotive, and industrial battery production.

Ensures Uniform Electrolyte Distribution

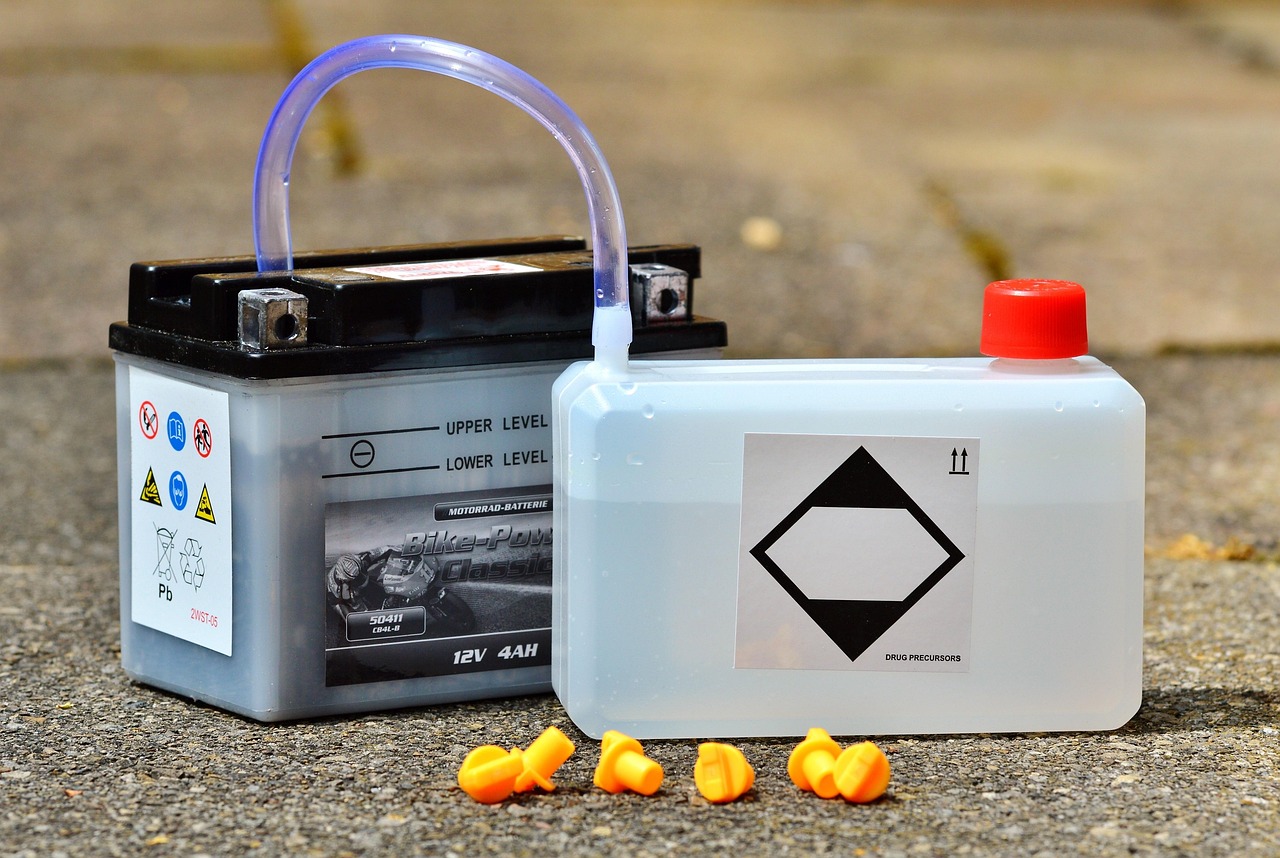

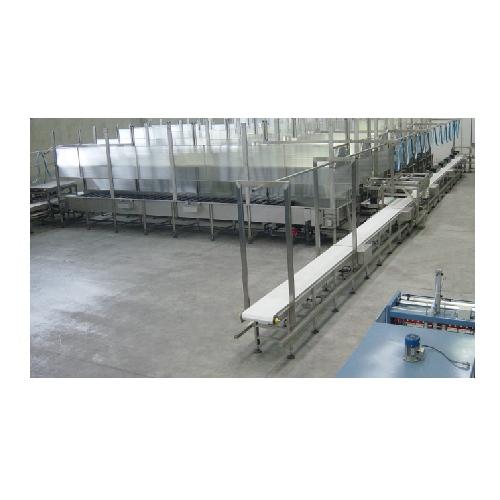

The Water Bath Formation System from Sovema Group is a specialized unit designed for the precise formation of lead-acid batteries. This system ensures uniform electrolyte penetration by submerging batteries in a controlled water bath, critical for the consistent performance of automotive, industrial, and deep cycle batteries. With a robust design, it accommodates various battery types and sizes, making it versatile for different production demands. Its automation capability integrates seamlessly with existing production lines, featuring a user-friendly PLC interface for monitoring and controlling the formation process. This system offers enhanced energy efficiency, reducing operational costs while maintaining high throughput. For durability and longevity, it is constructed with corrosion-resistant materials suitable for harsh industrial environments. Ideal for final conditioning departments, this system is essential for optimizing battery life and efficiency.

Benefits

- Enhances battery performance through consistent electrolyte distribution.

- Reduces operational costs with energy-efficient processes.

- Integrates seamlessly into existing production lines with automated controls.

- Minimizes maintenance needs with corrosion-resistant construction.

- Accommodates a wide range of battery sizes for flexible production.

- Applications

- Batteries

- End products

- Lead-acid batteries, Industrial batteries, Automotive batteries, Deep cycle batteries, Agm batteries

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Working mechanism

- Water bath

- Integrated steps

- Formation process

- Automation level

- Automatic

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank Shape

- Rectangular / Circular

- Tank Size

- 500–5000 L

- Feed/Discharge Method

- Automatic / Manual