Standalone unit for serialization printing and verification

Ensure precise serialization and robust data integrity for pharmaceutical packaging with a compact, high-speed system that seamlessly integrates into your production line, enhancing both in-line and off-line operations.

Prints and Verifies Serialized Data on Cartons

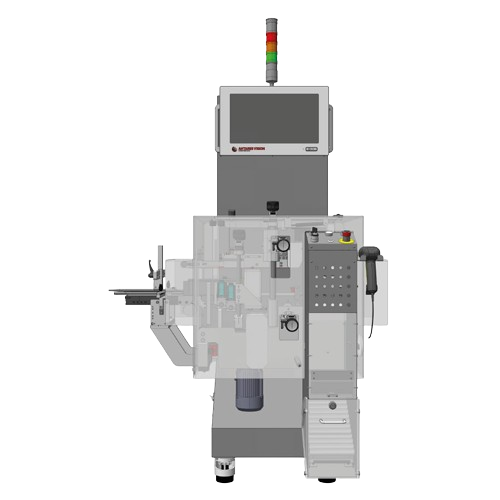

The Print & Check EVO (VM2100) from Antares Vision Group is a standalone serialization and verification system designed to streamline pharmaceutical packaging operations. This compact unit efficiently integrates into both in-line and off-line production setups to mark, record, and verify serialization data on cartons. Utilizing up to four thermal inkjet (TIJ) printing heads, it ensures high-resolution prints on both sides of the carton, achieving a line speed of up to 300 pieces per minute. With control cameras positioned for real-time inspection, it detects and rejects non-compliant products, maintaining data integrity and compliance with industry standards. Particularly suited for serialized medicine packages like cartons, blister packs, and vial packaging, the system incorporates flexible configurations for varying carton sizes. Its robust construction with options for water-based or solvent-based ink cartridges ensures adaptability and operational longevity. Moreover, it complies with ISO/IEC 15415-2 standards, supporting both pharmaceutical manufacturers and packaging companies in their serialization and regulatory efforts.

Benefits

- Enhances data integrity with real-time verification and rejection of non-compliant products.

- Increases production efficiency by printing and verifying at high speeds, up to 300 pieces per minute.

- Supports regulatory compliance with ISO/IEC 15415-2 standard for DataMatrix print quality.

- Offers flexible integration with upstream and downstream systems in packaging lines.

- Minimizes operational errors with dual-side printing and inspection capabilities.

- Applications

- Packaging solutions for life sciences, Printed cartons, Serialization of cartons, Pharmaceutical packaging

- End products

- Ampoule packaging, Pharma bottles, Medicine cartons, Serialized medicine packages, Blister packs, Printed pharmaceutical boxes, Pharmaceutical labels, Vial packaging, Folding cartons for pharmaceuticals

- Steps before

- Carton Preparation, Box Formation, Material Loading

- Steps after

- Product Conveyance, Packaging, Quality Assurance

- Input ingredients

- cartons, serialization data

- Output ingredients

- printed cartons, verified cartons, rejected cartons

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Speed

- Up to 300 pcs/min

- Working Height

- 800-1000 mm

- Conveyor Length

- 700 mm (+ 300 mm infeed conveyor)

- Printing Heads

- Up to 4 (2 each printable side)

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical

- Up to Grade A

- Carton Size

- A = 30-120 mm / B = 15-110 mm / C = 45-250 mm

- N. of Cameras

- Up to 2

- Standard Controls

- 1D/2D Code Recognition and Print Quality Evaluation

- Automation level

- Standalone automatic

- Line speed

- Up to 300 pcs/min

- Printing sides

- 2 sides (operator side and machine side)

- Conveyor system

- Input belt with infeed conveyor

- Marking and verification

- Inline serialization

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact

- Conveyor Length

- 700 mm

- Working Height

- 800-1000 mm

- Standard Carton Size (mm)

- A = 30-120 / B = 15-110 / C = 45-250

- Final Exit/Discharge Method

- Conveyor with Rejection Containers

- Printable Sides

- 2 Sides

- Printing Heads

- Up to 4 (2 each side)

- Control panel type

- HMI/Touchscreen

- Integration possibilities

- Upstream checkweigher coupling

- Printing heads

- Up to 4 (2 each printable side)

- Printing system

- TIJ 2.5 including print controller