Presses and furnaces for metal powder components

Achieve precise forming and consistent quality in metal components production with advanced pressing and thermal treatment solutions, streamlining processes from powder to finished parts in an efficient and flexible manner.

Integrates Pressing, Automation, and Thermal Treatment

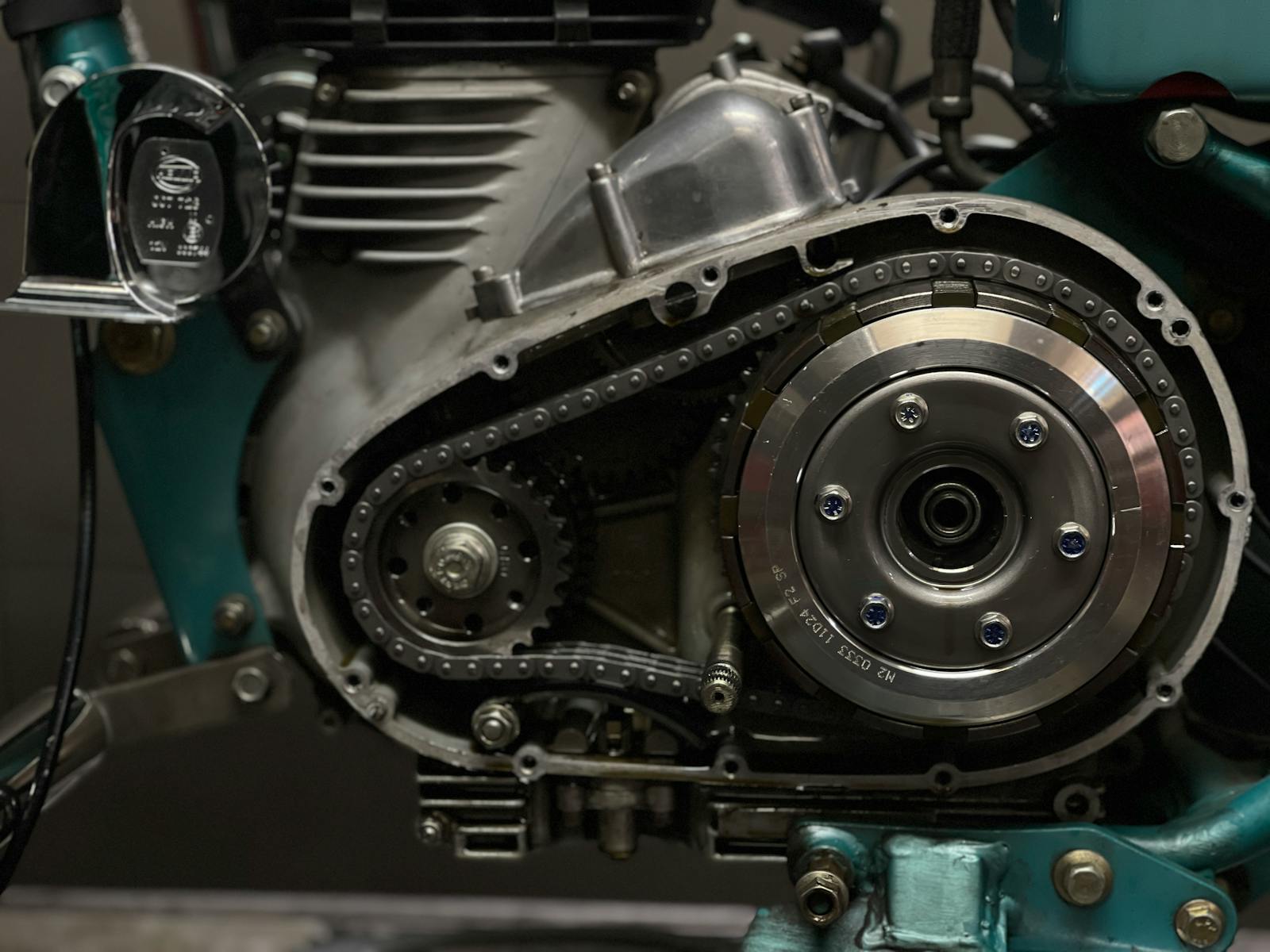

The MPH Metal Powder Presses from SACMI are engineered to transform the landscape of powder metallurgy and metal manufacturing. Specially designed for continuous, high-speed production, these presses streamline the pressing of metal powders into precise components, including bearing parts, gears, and tungsten carbide tools. The MPH series operates with a sophisticated hydraulic system that enhances precision and reduces setup times.

Capable of handling diverse applications, from automotive to aerospace industries, the presses support the production of sintered metal components and metallurgical products through integrated pressing, automation, and thermal treatment processes. These presses offer significant energy savings with their optimized motor control, reducing operational costs while maintaining environmental sustainability.

Automated features enable seamless integration into existing production lines, enhanced by SACMI’s Assisted Programming Interface (API) for flexible operation control. Built from robust materials, the MPH presses offer excellent durability and corrosion resistance, suitable for challenging industrial environments. They come with support for customization and engineering support, ensuring the configuration aligns with specific operational needs.

Benefits

- Enhances production efficiency with faster setup times and high-speed operation.

- Lowers operational costs by reducing energy consumption through optimized motor control.

- Facilitates seamless integration with existing systems via automated features and API support.

- Ensures component precision and consistency in challenging industrial environments.

- Offers tailored configurations to meet specific production requirements through customizable options.

- Applications

- Hard metal components, Metal powders, Powder metal components, Industrial kiln products

- End products

- Furnace treated metal parts, Sintered metal components, Bearing components, Engine components, Structural parts, Metallurgical products, Cutting tools, Tungsten carbide tools, Gears, Machinery parts

- Steps before

- Metal Powder Preparation, Blending, Mixing

- Steps after

- Sintering, Finishing, Quality Control, Packaging

- Input ingredients

- metallic powders, metal powder components

- Output ingredients

- metal components, pressed metal parts, fired metal alloys

- Market info

- Sacmi is renowned for manufacturing advanced industrial equipment, primarily focusing on ceramics, packaging, and food processing. With a commitment to innovation and quality, Sacmi is a market leader in providing engineered-to-order solutions across various sectors.

- Production rate

- High

- Set-up time

- Reduced

- Energy consumption

- Low

- Sustainability

- High

- Automation

- Assisted Programming Interface (API)

- Reliability

- High

- Press technology

- Hydraulic

- Experience

- 90 years in firing technology

- Kiln plants range

- World's widest

- Working Mechanism

- Hydraulic Press

- Integrated Steps

- Pressing, Automation, Thermal Treatment

- Batch vs Continuous Operation

- Batch

- Automation Level

- Assisted Programming Interface (API)

- Energy Efficiency

- Energy saving

- Changeover Time

- Reduced set-up times

- Reliability

- Global Network Support

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Assisted Programming Interface (API)

- Integration possibilities

- Industrial automation systems

- Degree of personalization

- Highest level available