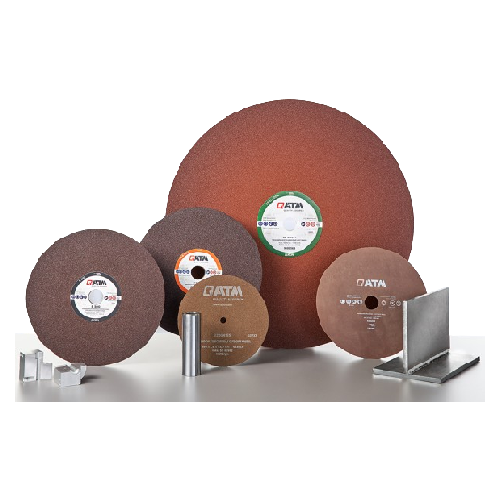

Premium cut-off wheels for metallographic sample preparation

Achieve precise cuts with minimal deformation and temperature impact across various materials, from hard steels to delicate ceramics, ensuring optimal sample preparation for your metallographic analysis.

Cuts and Prepares Metallographic Samples

QPREP Premium Cut-off Wheels from ATM Qness GmbH are engineered for precision in metallographic sample preparation across various industries. These advanced wheels leverage tailored abrasive compositions, including silicon carbide, aluminum oxide, diamond, and cubic boron nitride, matched with specific bond types like resin, rubber, and bronze to minimize deformation and thermal effects. Ideal for applications involving non-ferrous metals, ceramics, and superalloys, these wheels ensure minimal material distortion and extended service life. Use them manually or in automatic setups to cut materials such as copper wiring, glass lenses, and turbine blades effectively. The cut-off wheels are designed for seamless integration into metallography workflows, supported by user-friendly color coding for easy selection. Whether cutting hard steels or polymers, these wheels meet stringent quality and performance standards, providing reliable and efficient processing in research, laboratory, and industrial environments.

Benefits

- Enhances cutting precision while minimizing material deformation and heat generation.

- Extends wheel lifespan, reducing operational costs and downtime.

- Adapts to diverse materials, ensuring versatility in laboratory and industrial settings.

- Simplifies material selection with intuitive color-coded identification.

- Supports efficient workflow integration, boosting productivity in metallographic processes.

- Applications

- Polymers, Ceramics, Stone, Non-ferrous metals, Ferrous metals, Metallographic samples, Glass, Hard steels, Refractory metals, Composite materials, Mineral rocks, Superalloys

- End products

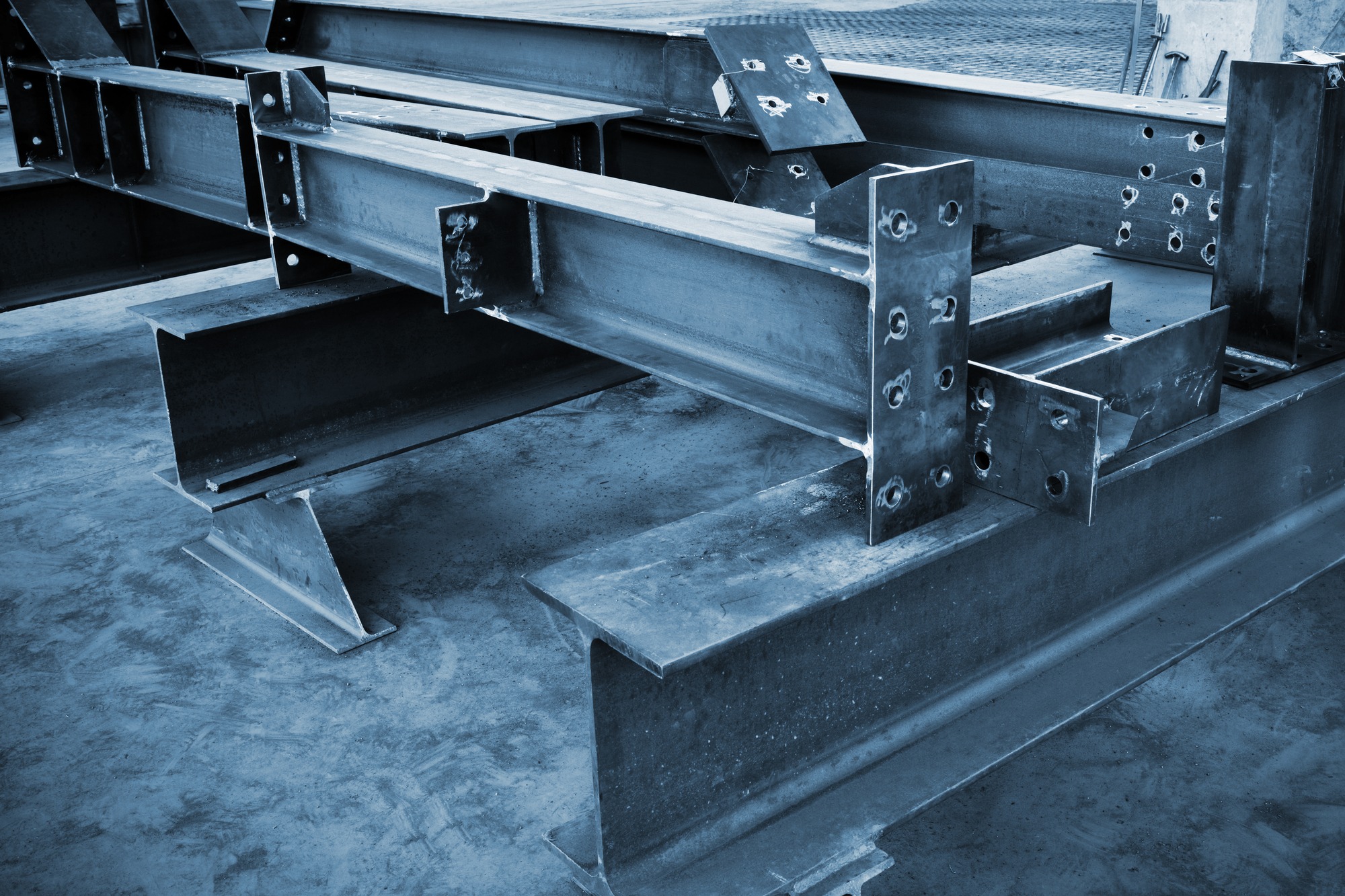

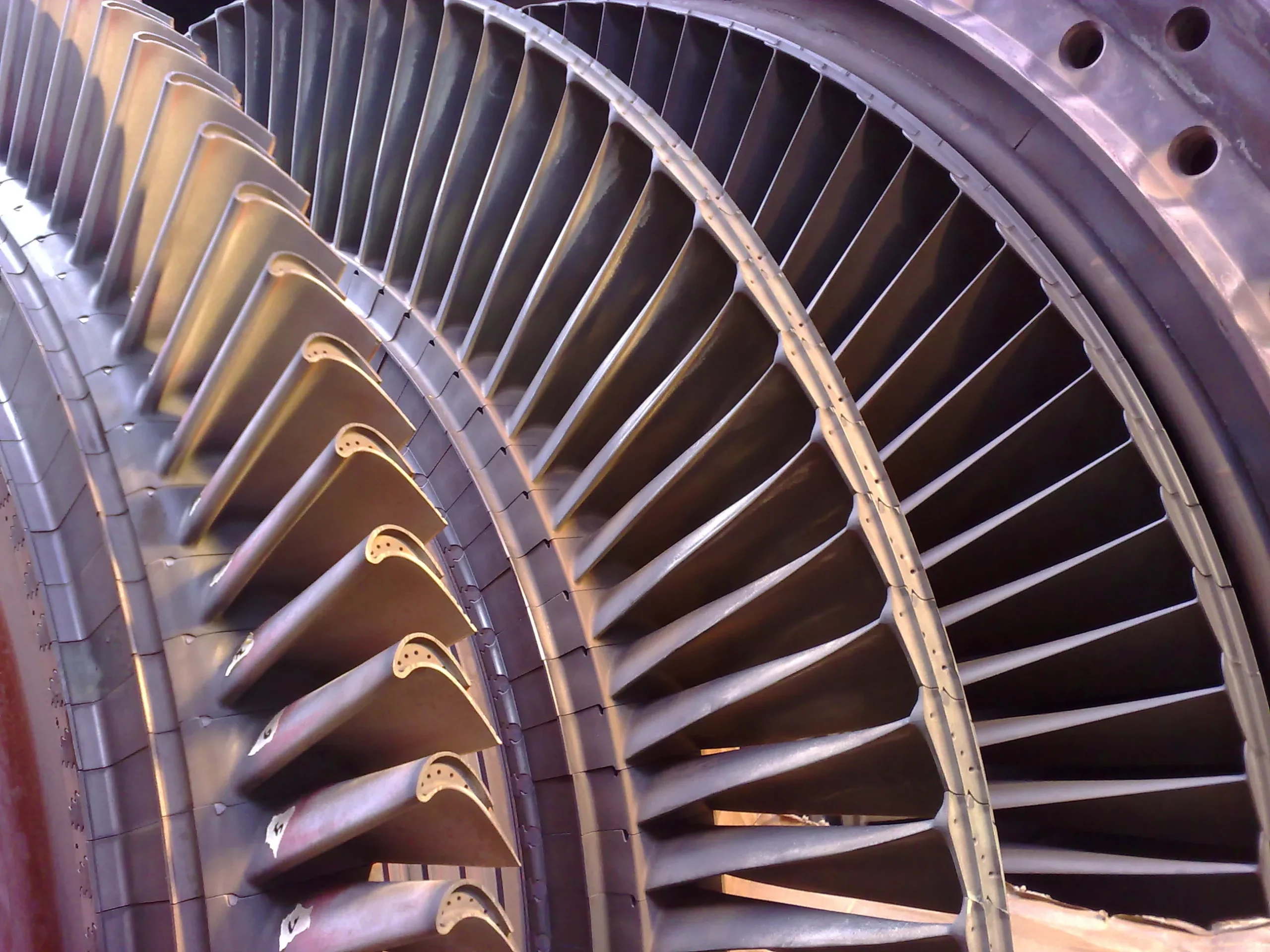

- Copper wiring, Steel beams, Weld rod samples, Heat exchanger components, Aircraft components, Ceramic tiles, Brass fittings, Turbine blades, Aluminum sheets, Marble countertops, Plastic casings, Hardened gear sections, Fiber-reinforced panels, Glass lenses

- Steps before

- Sample Preparation, Material Sectioning, Fixture Clamping

- Steps after

- Grinding, Polishing, Etching, Hardness Testing

- Input ingredients

- soft metals, hard metals, superalloys, high-speed steels, heat-treated steels, non-ferrous metals, Ti alloys, refractory metals, nickel and cobalt-based alloys, composite materials, ceramics, glass fiber reinforced plastics, minerals, rocks, glass, brittle coatings

- Output ingredients

- separated metal samples, cut composite materials, cut ceramic pieces, cut glass and minerals, cut hard steels

- Market info

- QATM is renowned for its expertise in manufacturing high-quality metallographic equipment and consumables, providing innovative solutions for material testing and analysis, which are trusted by laboratories and quality control professionals globally.

- Abrasion resistance

- High

- Bond Type

- Resin / Metal / Rubber / Bronze

- Lifetime

- Long

- Temperature effect

- Minimal

- Deformation

- Low

- Abrasive used

- Silicon carbide / Aluminum oxide / Diamond / CBN

- Cutting surface

- Fine

- Cutting performance

- Very good

- Cutting of soft metals

- Optimized

- Cubic boron nitride (CBN) performance

- High ductility

- Thermal conductivity

- Effective

- Cutting mechanism

- Abrasion

- Temperature control during cutting

- Minimized temperature effect

- Deformation control

- Low deformation

- Automation level

- Manual / Automated systems

- Changeover time

- Quick visual assignment

- Cutting performance optimization

- Based on material hardness

- Cut-off wheel material compatibility

- Wide range of materials

- Bond type customization

- Metal / Resin / Rubber

- Abrasion resistance

- Yes

- Hardness compatibility

- Soft to very hard materials (30 HV to >700 HV)

- Material type

- Metals, non-ferrous metals, superalloys, ceramics, composites

- Cutting performance

- Optimized for minimal deformation and low temperature effects

- Temperature resistance

- Low temperature generation during cutting

- Wear resistance

- Long lifetime and low wear applications

- Bond type

- Resin, rubber, bronze

- Abrasive type

- Aluminum oxide, silicon carbide, diamond, cubic boron nitride (CBN)

- Corrosive resistance (e.g. acids)

- N/A

- Abrasive Type

- Aluminum oxide, Silicon carbide, Diamond, CBN

- Bond Type

- Metal, Resin, Rubber, Bronze

- Color Coding

- For quick identification

- Abrasive selection

- Aluminum oxide / Silicon carbide / Diamond / CBN

- Bond type

- Metal / Resin / Rubber

- Cut-off wheel size

- Varies by application

- Color coding system

- Material hardness based

- Material compatibility

- Soft metals / Hard metals / Ceramics / Composites

- Integration compatibility

- Benchtop / Floor-standing machines

- Special features

- Dressing function for abrasives