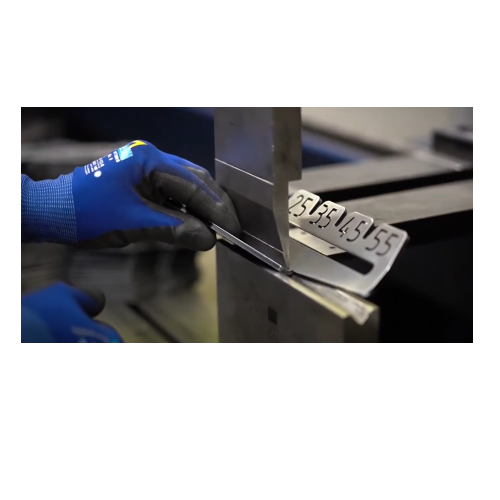

Precision metal bending and forming service

Elevate your production capabilities with precise metal forming solutions that ensure optimal component shaping, seamless integration, and enhanced efficiency across diverse manufacturing processes.

Processes and Fabricates Metal Components Efficiently

The SPALECK CNC Precision Bending and Laser Cutting System is a comprehensive solution for metal fabrication that combines cutting-edge technology with skilled engineering. This equipment excels in processing metal components by utilizing advanced CNC machining centers and laser cutting machines for precise bending, cutting, and shaping. Designed for diverse applications, it caters to wind energy manufacturers and automotive industries, producing sheet metal brackets, turbine casings, and automotive chassis parts.

The system boasts a high throughput, efficiently managing a wide range of tasks from bending and forming to welding and coating. Automation is enhanced through robotic welding systems and a PLC-controlled interface, allowing seamless integration into existing production lines with real-time monitoring. Energy efficiency is prioritized with optimized motor control, reducing consumption by 30%.

Fabricated from durable materials, the system is engineered for corrosion resistance, with options available in high-grade stainless steel. Compliance with industry standards and certifications ensures reliability and safety across operations. For ease of maintenance, SPALECK provides a streamlined cleaning process complemented by engineering support for tailored customization, ensuring the equipment meets unique production requirements.

Benefits

- Enhances production efficiency with seamless process integration and automation.

- Reduces operational costs with energy-efficient motor systems.

- Ensures precision and reliability in metal fabrication, supporting high-quality end-products.

- Minimizes maintenance time with easy-to-clean design and robust material options.

- Adaptable to various industries, from automotive to food production, broadening application scope.

- Applications

- Metal parts, Wind turbines, Automotive components, Agricultural machinery, Food production equipment, Chemical production equipment

- End products

- Sheet metal brackets, Automotive chassis parts, Chemical processing vessels, Tractor components, Stainless steel tanks, Turbine casings

- Steps before

- Laserschneiden, Material preparation, Design and engineering

- Steps after

- Schweißen, Oberflächenbearbeitung, Baugruppenmontage, Quality assurance

- Input ingredients

- bleche, werkstücke, stahl, rostfreier edelstahl, aluminium, metallbauteile

- Output ingredients

- laserteile, schweißbaugruppen, kantteile, geformte werkstücke, metallwerkstücke, präzisionsteile

- Market info

- Spaleck is known for its expertise in designing and manufacturing innovative screening, separation, and conveying technology, particularly for recycling and bulk materials industries, and is reputed for high-quality, durable equipment tailored to customer specifications globally.

- Material Compatibility

- Stainless Steel, Aluminum, Steel

- Precision

- High Precision Bending

- Automation

- Fully Automated Robotics Welding

- Forming Type

- Bending and Rolling

- Processing Speed

- Fast processing

- Cost Efficiency

- Economical Pricing

- Production Capacity

- Large Volume Production

- Complexity Handling

- Handling Complex Assemblies

- Surface Treatment

- Coating and Finishing

- Compliance

- Diverse Industry Standards

- Working Mechanism

- Bending Press

- Automation Level

- Manual / PLC Controlled

- Changeover Time

- Quick setup

- Efficiency

- Cost-effective

- Batch vs. Continuous Operation

- Batch

- Metals processed

- Steel, Stainless Steel, Aluminum

- Metal type compatibility

- Steel / Stainless Steel / Aluminum

- Product form

- Sheets, Workpieces

- Press capacity

- High tonnage

- Control panel type

- Digital touch screen

- Discharge method

- Automated or manual

- Material processed

- Steel, stainless steel, aluminum

- Bending precision

- High precision, ±0.1 mm

- Material Type for Bending

- Stainless Steel / Aluminum / Steel

- Bending Machine Type

- Press Brake

- Bending Precision

- High Precision

- Automation Level for Bending

- Manual / Semi-Automatic / Automatic

- Custom Design Capabilities

- Yes

- Thickness Capacity

- Custom based on material