Precision cut-off system for materialographic samples

Achieve precise, repeatable cuts essential for high-quality metallographic and materialographic sample preparation, ensuring accurate microstructural analysis and reliable results in research and quality assurance processes.

Performs Precision Cutting and Sample Preparation

The Qcut 200 A from QATM is a benchtop precision cut-off machine designed for detailed metallographic sample preparation. Delivering accuracy and versatility, it features up to three automatic axes for precise cutting operations. Integral to laboratories focused on metallurgy, material science, and engineering research, it enables the effortless preparation of metallic specimens and microstructural samples. The machine’s advanced cooling system enhances cut-off wheel longevity, reducing wear by up to 15%, while automatic cleaning functions maintain efficiency and operational cleanliness.

Intuitive controls, including a large 7″ touch display and joystick, ensure ease of operation. With its modular design, the Qcut 200 A can be equipped with various clamping tools to accommodate diverse sample types. Designed for safety, the machine integrates an enabling switch and automatic component detection, reducing operator risk. Suitable for industries such as automotive, aerospace, and electronics, the Qcut 200 A aligns with the needs of both research and quality assurance departments, offering a reliable solution for precision cutting and sample integrity preservation.

Benefits

- Ensures precise and high-quality cuts, enhancing metallographic sample accuracy.

- Minimizes cut-off wheel wear by up to 15%, reducing maintenance costs.

- Enhances operator safety with two-hand control and automatic component detection.

- Offers flexible sample preparation with modular clamping options.

- Streamlines cleaning operations with automatic chamber and component cleaning functions.

- Applications

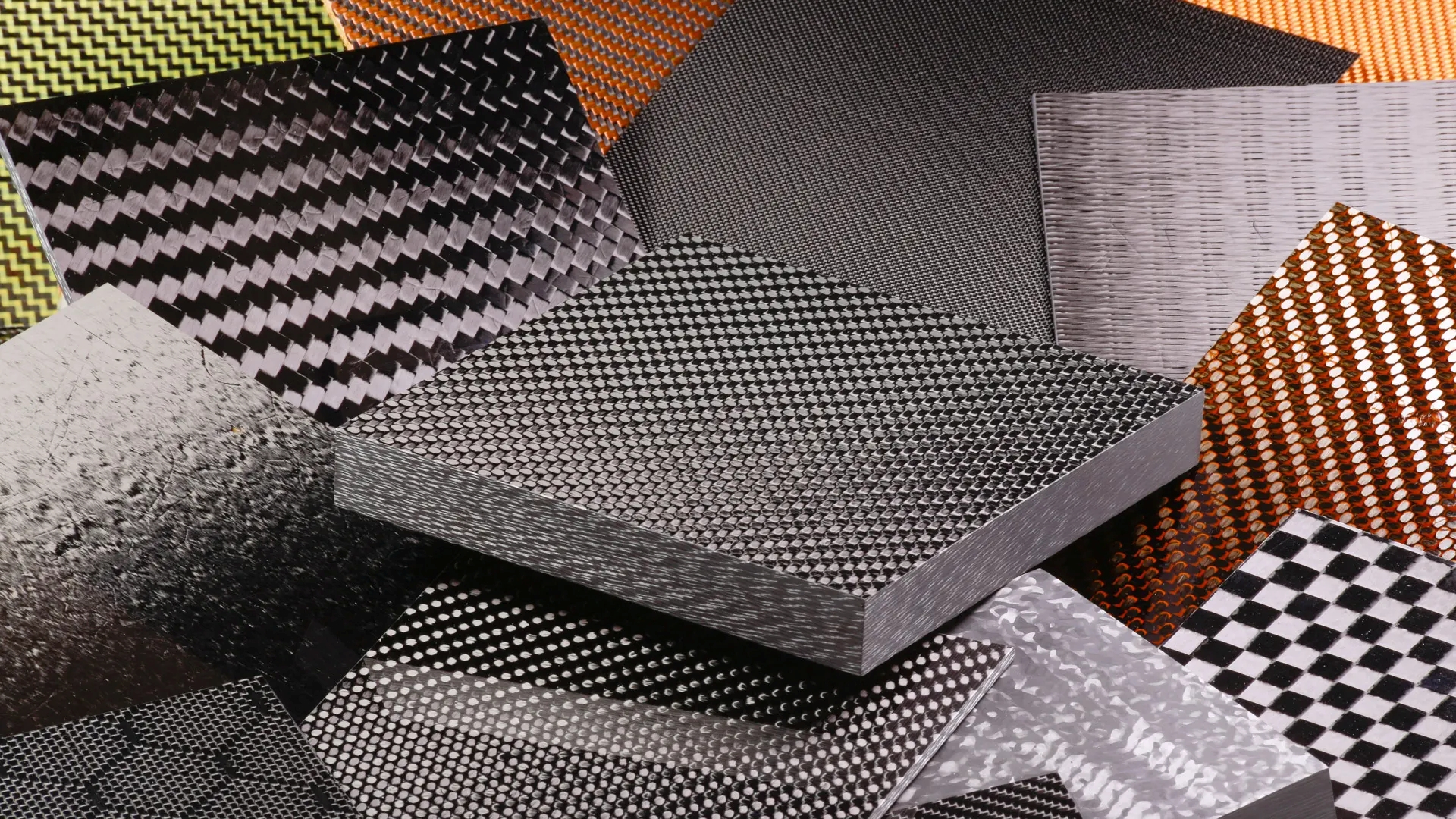

- Materialography, Research and development, Sample preparation, Quality assurance, Metallography, Hardness testing, Microscopy, Precision cutting, Metallurgical analysis, Material testing, Engineering materials

- End products

- Quality control test specimens, Prepared samples for microscopy, Metallic specimen sections, Metallographic cross-sections, Precision-cut metal parts, Engineering material samples, Laboratory-prepared specimens, Microstructural samples, Research development samples, Metallurgical samples

- Steps before

- Mounting, Clamping, Sample Preparation

- Steps after

- Cleaning, Polishing, Hardness Testing, Etching, Material Analysis

- Input ingredients

- material samples, workpieces, solid material, sensitive samples, glass slides for thin sections

- Output ingredients

- cut components, prepared samples, material sections, thin sections

- Market info

- QATM is renowned for its expertise in manufacturing high-quality metallographic equipment and consumables, providing innovative solutions for material testing and analysis, which are trusted by laboratories and quality control professionals globally.

- Cut-off wheel diameter

- up to Ø 203 mm / 8"

- Max. cutting capacity

- 75 mm (cut-off wheel Ø 200 mm)

- Wheel flange size

- Ø 12.7 mm

- X-axis movement

- 210 mm (manual / automatic)

- Y-axis movement

- 80 mm (automatic)

- Z-axis movement (optional)

- 80 mm (automatic)

- Feed rate

- 0.01 - 20 mm/s

- Precision of Z-axis

- 0.005 mm

- Minimum cross feed (Z-axis)

- 0.001 mm

- Table size without Z-axis

- 300 x 210 mm

- Table size with Z-axis

- 280 x 210 mm

- T-slot size

- 8 mm

- Speed

- 300 - 5000 rpm

- Drive power (main drive)

- 0.75 kW, S1

- Connection power

- 2.2 kVA

- Dimensions (W x H x D)

- 725 x 535 x 675 mm

- Weight

- ~ 82 kg

- Automation level

- Fully automatic / Manual

- Batch vs. continuous operation

- Batch

- Cleaning method

- Automatic Cleaning

- Changeover time

- Simplified cut-off wheel change

- Operation Interface

- 7" touch display with joystick control

- Safety features

- Two-hand control with enabling switch

- Component detection

- Automatic component and exit detection

- Cooling system

- Approximately 25% higher flow rate

- Flow monitoring

- Optional for constant cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Benchtop model

- Control Panel Type

- 7" TFT touch display

- Intelligent Component Detection

- Automatic component and exit detection

- Automatic Axes

- Up to 3 automatic axes (X, Y, Z)

- Software Integration

- User-friendly software with new functions

- Clamping System

- Easy clamping system

- Modular Adaptable Turning Device

- Available as an accessory

- Flow Monitoring System

- Optional for constant cooling

- Enabling Switch

- Two-hand control for safety