Pharmaceutical pellet spheronizers

Achieve uniform spherical pellets for reliable drug delivery with a spheronizer designed to enhance consistency and efficiency in pharmaceutical production.

Processes Pharmaceutical Powders into Spherical Pellets

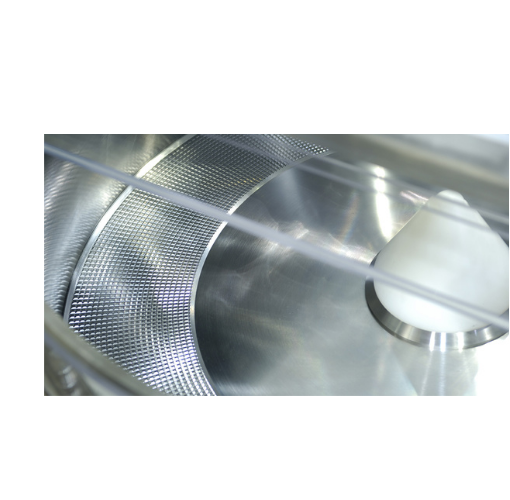

The NICA Spheronizer System from GEA is specifically engineered for pharmaceutical manufacturers seeking to optimize pellet production. Utilizing a horizontal spinning wheel with a patented ‘smooth edge’ friction design, the NICA system effectively transforms spaghetti-like extrudates into uniform spherical pellets, minimising attrition and reducing spheronization time. This equipment supports both batch and continuous operations, integrating seamlessly into existing pharmaceutical processing lines. Available in models like the S450 and S700, it accommodates capacities from 2 kg to 10 kg, ideal for both small-scale production and high throughput demands. The system features interchangeable friction discs, pneumatic discharge, and air purging, ensuring efficient production with integrated speed control. Designed for the creation of controlled-release medication pellets and microspheres, the NICA Spheronizer System complies with industry standards, offering reliable performance and ease of maintenance essential for advanced drug delivery applications.

Benefits

- Ensures consistent pellet quality with narrow size distribution, critical for uniform drug delivery.

- Increases production efficiency by reducing spheronization time through optimized friction design.

- Enhances process flexibility with interchangeable wheel patterns, accommodating diverse product requirements.

- Supports seamless integration and automation within production lines, minimizing manual intervention.

- Facilitates easy cleaning and maintenance, ensuring compliance with stringent pharmaceutical standards.

- Applications

- Pellets, Spherical pellets, Pharmaceutical powder, Pharmaceuticals

- End products

- Spherical bioactive ingredient pellets, Multivitamin beadlets, Controlled-release medication pellets, Sustained-release capsule fillers, Enteric-coated drugs, Microspheres for drug delivery

- Steps before

- Extrusion, Batching

- Steps after

- Pellet Drying, Coating, Tablet Pressing, Packing

- Input ingredients

- extrudates, spaghetti-like extrudates, extruded mass

- Output ingredients

- spherical pellets, spheres

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Batch capacity (S450)

- 2 kg

- Batch capacity (S700)

- 2–10 kg

- Product throughput (S700)

- Up to 10 kg

- Friction wheel pattern

- Interchangeable

- Drive type

- Variable speed inverter drives

- Pneumatic discharge

- Standard (S450 and S700)

- Operation type

- Batch and continuous

- Spheronization time

- Reduced

- Size distribution control

- Narrow size distribution

- Process modules

- IPS5, IPS25, IPS50, IPS100, IPS200

- Smooth edge design

- Patented

- Air purge conditioning

- Yes

- Electronic speed control

- Yes

- Working mechanism

- Horizontal spinning wheel

- Integrated steps

- Extrusion and spheronization

- Batch vs. continuous operation

- Batch and Continuous

- Automation level

- Variable speed inverter drives, pneumatic discharge

- Cleaning method

- Easy operation and cleaning

- Changeover time

- N/A

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Spinning wheel diameter

- S250, S450, S700

- Friction wheel pattern

- Interchangeable

- Machine size

- Compact

- Discharge method

- Pneumatic discharge valve

- Bowl shape

- Cylindrical