Linear transfer line exchanger for ethylene plants

Rapidly cools furnace effluent in ethylene plants to optimize performance and prevent material degradation, ensuring efficient downstream processing.

Rapidly Cools and Quenches Cracked Gas

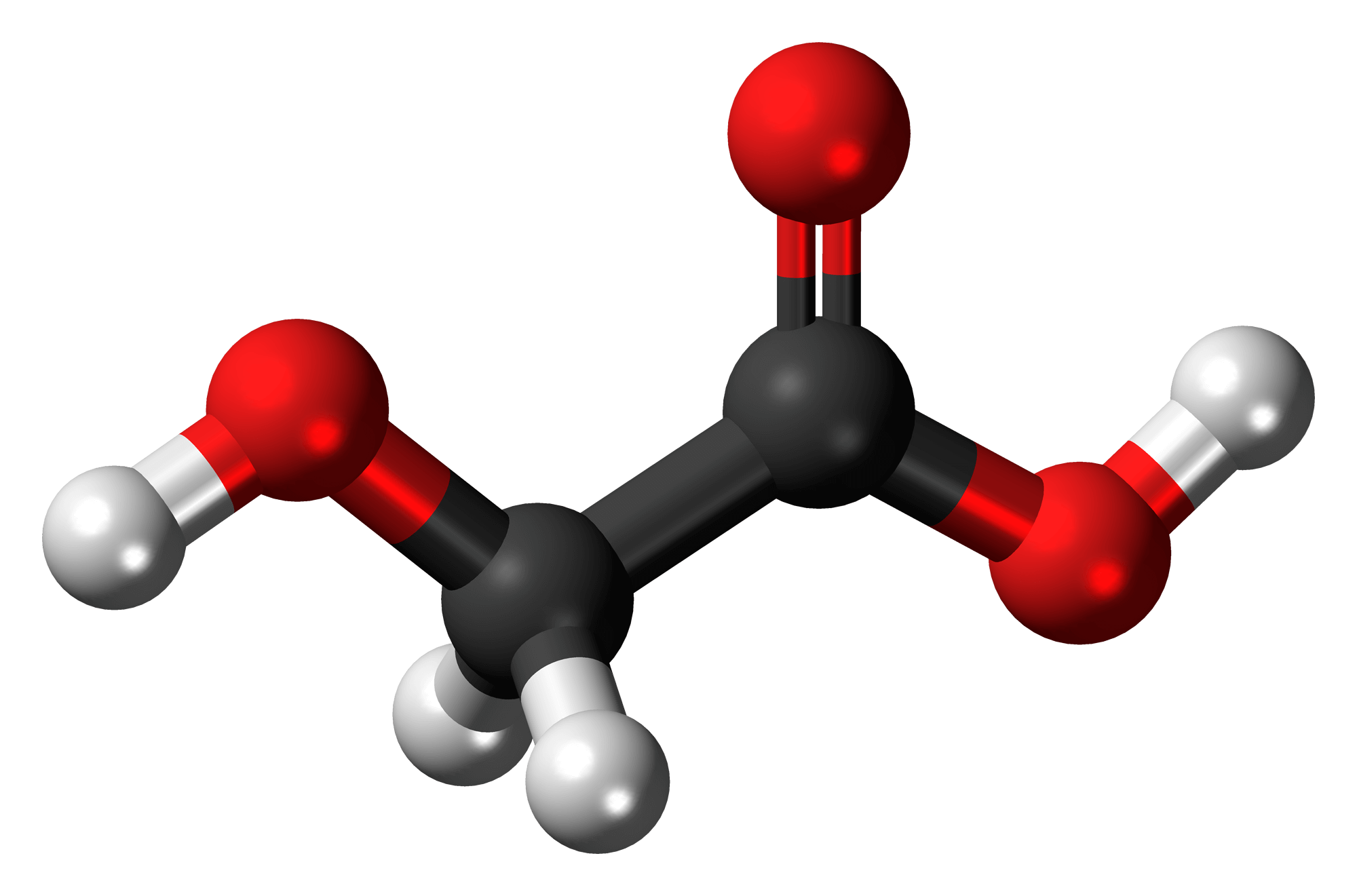

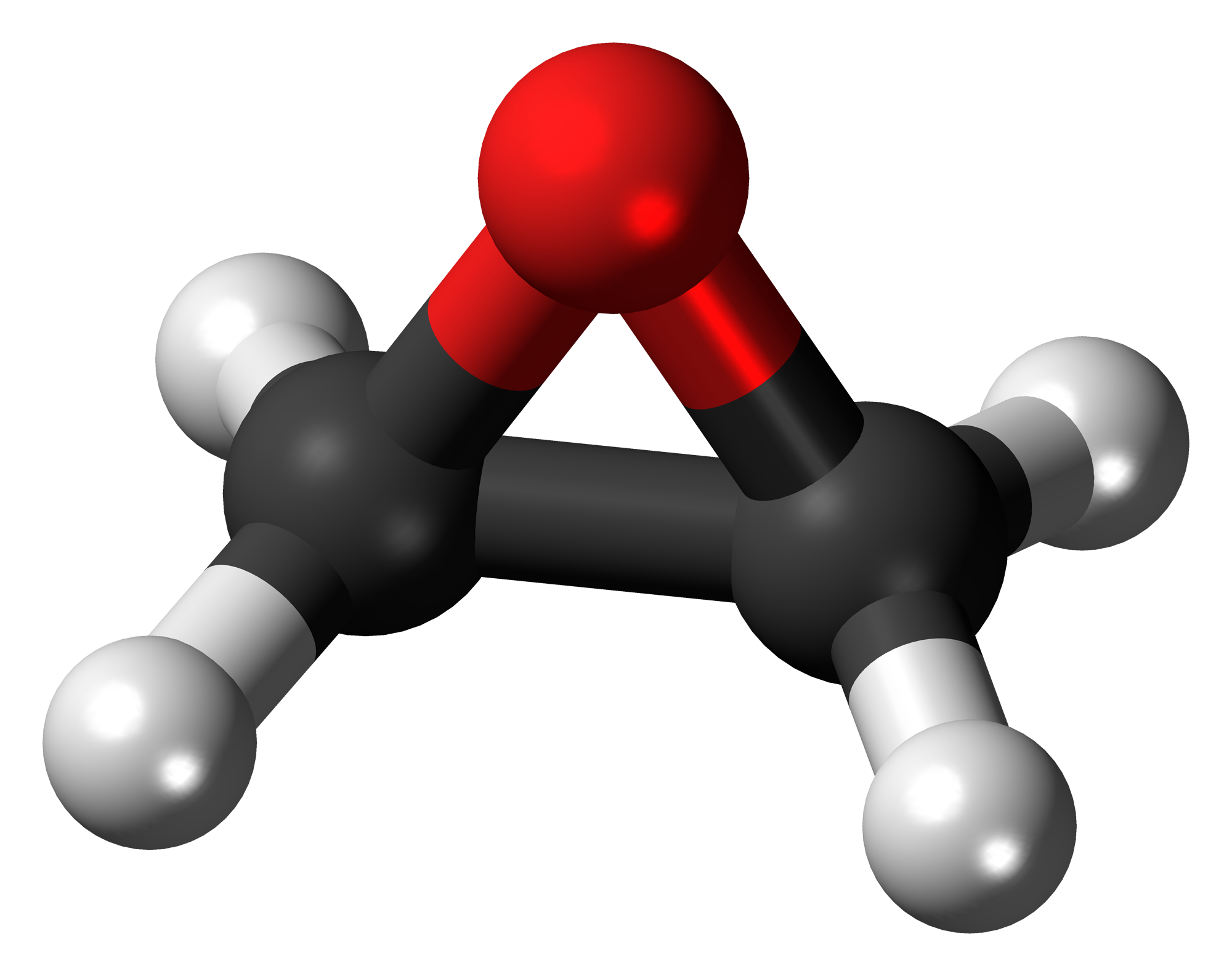

The BORSIG Linear Transfer Line Exchanger efficiently addresses the cooling and quenching requirements of ethylene furnace effluent. Utilizing its patented linear quencher design, it incorporates linearly arranged double pipe elements directly coupled to each furnace radiant coil outlet. This eliminates the need for complex fittings, minimizing fouling and erosion. Commonly applied in ethylene production, it supports processes like quenching and separation of cracked gas into ethylene, ethylene glycol, and polyethylene. With its compact, modular design, it enables easy integration into continuous operations and offers customizable configurations for single or twin-leg setups. The design ensures a low-pressure drop and reduced residence time, enhancing operational efficiency. Constructed for durability, it allows online decoking and includes maintenance-friendly features, fitting seamlessly within chemical and petrochemical industry environments. BORSIG’s extensive experience with over 6,000 installations worldwide affirms reliability and robust performance in challenging conditions.

Benefits

- Enhances production efficiency with minimal pressure drop and short residence time.

- Simplifies maintenance through online decoking, reducing operational disruptions.

- Versatile configurations accommodate space constraints, ensuring seamless integration.

- Minimizes fouling and erosion, extending equipment lifespan.

- Modular design allows easy scalability and customization for specific production needs.

- Applications

- Furnace effluent, Ethylene, Cracked gas

- End products

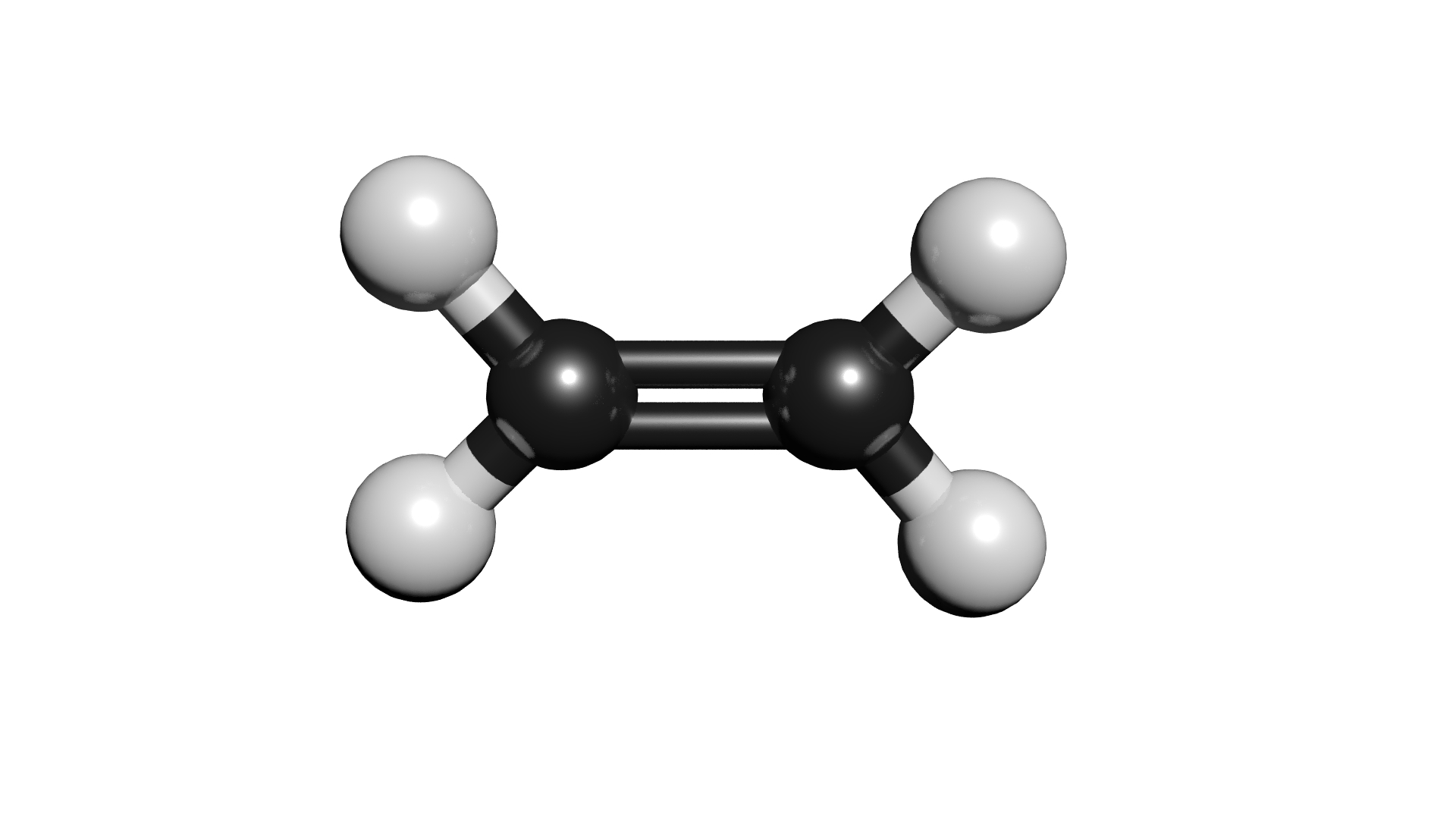

- Polyethylene, Ethylene dichloride, Ethylene glycol, Ethylene oxide

- Steps before

- Cracking in ethylene furnaces, Furnace radiant coil operation

- Steps after

- Steam collection and distribution, Quenching, Cooling of cracked gas

- Input ingredients

- cracked gas, process effluent from radiant coil

- Output ingredients

- cooled cracked gas, steam/water mixture

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Design

- Linear Double-Pipe

- Cooling Method

- Rapid Cracked Gas Cooling

- Quenching Process

- Individual Radiant Coil Quenching

- Connection Type

- Linearly Arranged Double Pipe Elements

- Steam/Water Distribution

- Common Downcomer and Riser Headers

- Boiler Water Circulation

- Common Downcomer Header

- Gas Side Volume

- Low Residence Time

- Pressure Drop

- Low Overall

- Decoking

- Online

- Flow Arrangement

- Upflow or Downflow

- Design Flexibility

- Single or Twin Leg Designs

- No Restrictions

- Quench Pipe Diameter

- Gas Inlet Heads

- Three Refractory, No Steam Purge Required

- Modularity

- Compact, Modular Design

- Working Mechanism

- Linear double-pipe quencher

- Integrated Step

- Cracked gas cooling

- Batch vs Continuous Operation

- Continuous

- Automation Level

- Manual / PLC

- Changeover Time

- Fast due to modular design

- Cleaning Method

- Ease of maintenance

- Upflow or Downflow Arrangement

- Both options available

- Energy Efficiency

- Low pressure drop

- Quench Pipe Diameter Restriction

- No restriction

- Machine footprint

- Compact, modular design

- Design type

- Double-pipe linear design

- Orientation

- Upflow or downflow arrangement

- Customization Option

- Single or twin leg designs

- Pipe diameter

- No restriction in quench pipe diameter

- Inlet heads

- Three refractory gas inlet heads

- Control panel type

- NA

- Discharge method

- NA

- Pipe Arrangement

- Single or Twin Leg

- Flow Direction

- Upflow or Downflow

- Module Design

- Modular

- Quench Pipe Diameter

- No Restriction

- Gas Side Volume

- Low

- Refractory Gas Inlet Heads

- Three

- No Steam Purge Required

- Chamber Design

- "Turboflow"

- Header System

- Common Water/Steam Header