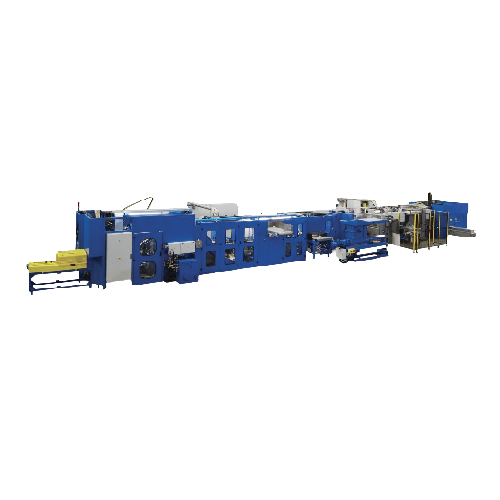

Industrial plate production line for battery manufacturing

Streamline your plate production workflow with a compact, efficient solution designed for high-precision output and seamless integration into existing lines.

Produces Solid Industrial Plates Efficiently

The IPPL from Sovema Group is a robust solution for industrial plate production, seamlessly integrating into your processing department. This equipment is engineered to deliver precision in solid plate fabrication, optimizing throughput while maintaining quality. Its design accommodates high production volumes with an efficient processing capacity tailored to meet demanding operational requirements. Fully compatible with automated production lines, the IPPL features advanced monitoring and control systems to ensure seamless integration and minimal manual intervention. Constructed from durable materials, the system offers superior corrosion resistance and is available in various configurations to suit specific production needs. Equipped with easy-to-access components, the IPPL facilitates straightforward maintenance and cleaning, reducing downtime and extending service life. Whether you’re upgrading or expanding your production line, Sovema Group offers customization and engineering support to align the IPPL with your unique specifications.

Benefits

- Streamlines production of solid plates, enhancing overall output efficiency.

- Integrates seamlessly into existing lines, reducing transition time and costs.

- Minimizes maintenance with easy-access components, increasing uptime.

- Provides high corrosion resistance, extending equipment lifespan.

- Supports custom configurations to meet specific production demands.

- Applications

- End products

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Production line type

- Industrial Plate Production

- Automation level

- Advanced/PLC

- Integration capability

- High

- Modular design

- Available

- Operation mode

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm