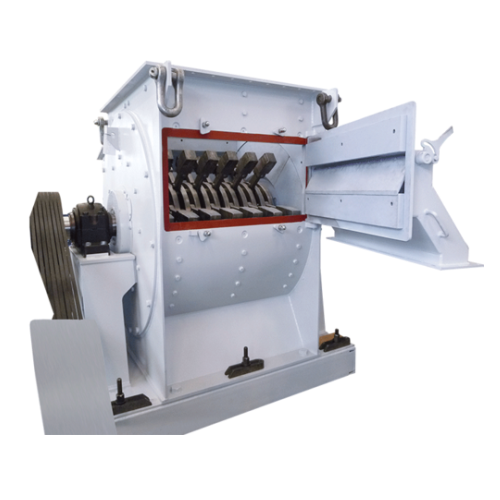

Industrial hammer mill for mineral processing

Optimize your material processing with an advanced hammer mill designed to efficiently grind, crush, and classify a wide range of materials from minerals to ceramics, ensuring consistent quality and enhancing your production capabilities.

Processes and Classifies Minerals and Ceramics

The Hammer Mill HM from NEUMAN & ESSER is engineered for minerals and ceramics processing, offering a robust solution for grinding, crushing, and classification. Its impact grinding principle ensures efficient size reduction, making it ideal for materials like gypsum, limestone, and clay. A continuous operation is achieved through a rotary airlock and fan system that maintains a stable material flow and discharge process. Capable of processing up to 50 tons per hour, the Hammer Mill HM delivers precise particle size limitation from 50 μm to 2,000 μm.

Designed for low maintenance, it automatically discharges challenging impurities, ensuring long service life for components. The mill’s integration into production lines is seamless, with PLC controls and adaptability for various operational conditions. Constructed with durable materials, it handles abrasives while allowing options for corrosion-resistant designs, ensuring compatibility with a range of processing environments.

Benefits

- Enhances production efficiency with continuous operation design.

- Prolongs component lifespan by automatically discharging abrasive impurities.

- Adapts to diverse processing demands with versatile particle size control.

- Minimizes maintenance needs through simple design and robust construction.

- Integrates seamlessly into existing systems with PLC-controlled automation.

- Applications

- Ceramics, Limestone, Clay, Gypsum, Minerals, Abrasive impurities

- End products

- Calcined gypsum plaster, Ceramic tiles, Porcelain pottery, Hydrated lime, Bentonite powder, Fine clay powder, Synthetic gypsum board, Bauxite powder, Natural gypsum powder, Quicklime

- Steps before

- Material Feeding, Particle Size Reduction, Pre-Classifying

- Steps after

- Air Separation, Dust Separation, Cyclone Collection

- Input ingredients

- soft to medium-hard grinding materials, minerals, bentonite, bauxite, synthetic gypsum, raw natural gypsum, calcined gypsum, CaO-limestone, Ca(OH)2– hydrated lime

- Output ingredients

- ground product, finished product, particles in sizes 50 μm – 2, 000 μm

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Grinding method

- Impact grinding

- Particle size limitation

- 50 μm – 2, 000 μm

- Throughput

- 0.1 t/h – 50 t/h

- Mill power

- 15 kW – 315 kW

- Air quantity

- 2, 000 m³/h – 60, 000 m³/h

- Feed material particle size

- 0 – 25 mm

- Feed material moisture

- 0 – 35 %

- Rotor diameter

- 500 mm – 2, 000 mm

- Operation mode

- Continuous

- Maintenance requirement

- Low

- Working Mechanism

- Impact grinding

- Feed Method

- Rotary airlock

- Airflow Regulation

- Controller adjusted air lock speed

- Discharge Method

- Automatic continuous discharge

- Operation Mode

- Continuous

- Maintenance Level

- Low maintenance

- Temperature Management

- High inlet air temperatures

- Dust Separation

- Air separator with dust removal

- Abrasion resistance

- Yes

- Cleanability

- Yes

- Density/particle size

- Suitable for 0 – 25 mm

- Grinding materials

- Soft to medium-hard minerals

- Application type

- Grinding, de-agglomeration, flash drying, classification

- Materials processed

- Clay, ceramics, gypsum, limestone

- Machine footprint

- Not specified

- Rotor diameter

- 500 mm – 2, 000 mm

- Feed material particle size

- 0 – 25 mm

- Feed material moisture

- 0 – 35%

- Compact footprint

- Not specified

- Discharge method

- Continuous

- With dust separator