In-transit wheel diagnosis for railways

Optimize railway safety and efficiency by diagnosing wheel imperfections in transit, reducing costly track damage and improving train reliability with continuous, automated monitoring.

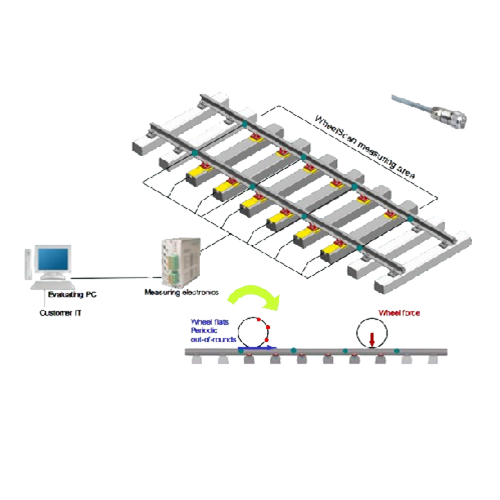

Diagnoses Wheels and Monitors Loads In-Transit

The MULTIRAIL WheelScan from Schenck Process is a sophisticated in-transit wheel diagnosis system designed for the efficient monitoring of rail networks. It accurately diagnoses wheel imperfections, monitors load distributions, and reduces noise emissions through its dynamic weighing capability. The system can operate at speeds from 10 km/h to 250 km/h, allowing it to integrate seamlessly into high-speed rail operations. Targeting railway companies and infrastructure managers, it prevents track damage by identifying potential hazards before they cause costly downtime or accidents. This system is EBA-approved and equipped with sensors to ensure long-term operational stability, offering automated track inspection and reduced personnel costs. The quick installation process is facilitated by pre-calibrated weighbeams that fit into existing tracks, requiring no new foundations. The technology supports continuous rail installations, delivering precise, real-time data essential for proactive maintenance and optimized railway logistics.

Benefits

- Prevents costly track damage and accidents with precise wheel diagnostics.

- Reduces maintenance costs by enabling timely, targeted repairs.

- Minimizes operational disruptions with fast installation and seamless integration.

- Enhances safety and efficiency by monitoring load distributions and noise emissions.

- Lowers personnel costs through automated track inspection and reduced manual oversight.

- Applications

- Wheel diagnosis, Railways, Transport logistics, Train monitoring, Track networks

- End products

- Rail tracks, Rail freight coaches, Train wheelsets, Train wagons, Railway passenger cars

- Steps before

- Track inspection preparation, Vehicle scheduling, Rail network setup

- Steps after

- Maintenance scheduling, Dynamic load analysis, Track repair planning, Noise reduction planning

- Input ingredients

- train wheels, wheel loads, load distributions

- Output ingredients

- wheel diagnostics, identified wheel imperfections, track load analysis, reduced noise emissions, safety reports, maintenance alerts

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Speed Range

- 10 km/h to 250 km/h

- Automation

- Automated track inspection

- Dynamic Force Measurement

- Yes

- Noise Emission Reduction

- Yes

- Installation Requirement

- Continuous rail installation

- Maintenance

- Direct appropriate maintenance

- Wheel Diagnosis Speed Range

- 10 km/h to 250 km/h

- Dynamic Force Detection

- Yes

- Automation of Track Inspection

- Automated

- Continuous Rail Installation

- Yes

- Installation Requirements

- No New Foundations Needed

- Personnel Requirements

- Reduced Personnel Costs

- Long-term Stability

- Yes

- Calibration Service

- EBA-approved

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Interactive HMI

- Integration possibilities

- Compatible with existing railway systems

- Installation type

- Continuous rail installation

- Scan speed

- 10 km/h to 250 km/h

- Detection system

- Full Scan for Reliable Train Detection

- Calibration service

- Calibration for dynamic forces

- Personnel requirements

- Reduced personnel costs