Graphite spheronization system for battery production

Enhance battery performance with precision spheronization of graphite materials, achieving optimal particle roundness and improved energy density for lithium-ion battery anodes.

Controls Particle Shape and Size for Anode Graphite

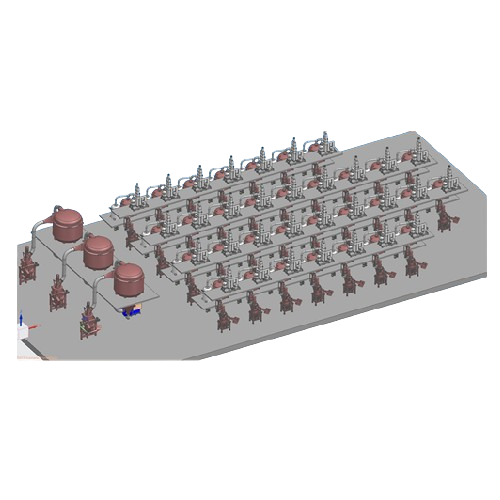

The Spheronizer NEA|Sphere from Neuman & Esser is engineered to optimize the production of spherical anode graphite for high-performance battery components. It utilizes a split process system involving separate grinding, classifying, and rounding phases, allowing precise control over particle size distribution and sphericity. Designed for continuous and automated operation, the equipment supports applications in battery manufacturing, renewable energy, and the chemical industry, specifically targeting lithium-ion battery anodes and energy storage systems. The NEA|Sphere achieves efficient spheronization with its high-intensity grinding tools and integrated classifier module to minimize superfines and maximize yield. It is available in both stainless steel and specialized alloys to ensure compatibility with various materials, accommodating the production of both synthetic and natural graphite. The equipment’s modular design facilitates integration into existing production lines and offers customization for specific throughput and material requirements. With advanced automation features, it provides enhanced operational efficiency, making it a reliable choice for industrial graphite producers.

Benefits

- Enhances battery performance by ensuring optimal particle sphericity and purity.

- Increases process yield by reducing ultrafine particles through precise separation.

- Offers scalable integration with existing production lines for flexible capacity expansion.

- Reduces operational costs with automated, high-speed processing.

- Provides material compatibility with corrosion-resistant options for diverse applications.

- Applications

- Natural graphite, Energy storage systems, Anode graphite, Petroleum coke, Synthetic graphite, Batteries, Graphite

- End products

- Lithium-ion battery anodes, Natural anode graphite, Petroleum coke-derived anode graphite, Synthetic anode graphite, Graphite anode materials, High-performance battery components, Spherical graphite

- Steps before

- Raw Material Selection, Purification, Initial Grinding

- Steps after

- Classification, Rounding, Further Separation, Quality Control

- Input ingredients

- natural flake graphite, petroleum coke, synthetic graphite

- Output ingredients

- spherical anode graphite, rounded particles, fine particles

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Particle Size Distribution

- Customizable to specific requirements

- Grinding Process

- High-intensity grinding tools

- Classification Module

- Highly efficient integrated

- Rounding Process

- Controlled spheronization

- Tapped Density Natural Graphite

- > 1g/ml

- Tapped Density Synthetic Graphite

- 0.7-0.9 g/ml

- Yield Improvement

- Significant increase

- Automation

- Integrated process control

- Material Type

- Natural/Synthetic graphite

- Process Complexity

- Reduced by splitting processes

- Fractionation Capability

- Narrow d90/d10 ratio handling

- Production Capacity

- High production capacities

- Working mechanism

- Grinding, Classifying, Rounding

- Integrated steps

- Grinding, Classifying, Spheronization

- Process complexity

- Reduced

- Automation level

- PLC controlled

- Batch vs. continuous operation

- Continuous

- Graphite compatibility

- Natural and Synthetic

- Spheronization compatibility

- High-performance battery materials

- Density/particle size

- 0.7–1 g/ml

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- SCADA / DCS Integration

- Module configuration

- Modular design for process scalability

- Spheronization tool

- Customizable for different materials