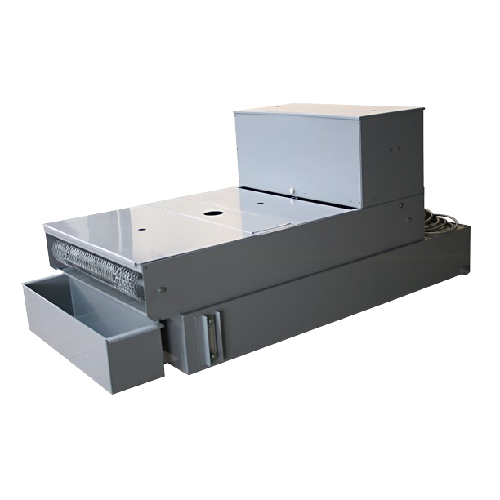

Filter systems for met cut-off contaminants

Ensure your cutting machines operate smoothly and efficiently by preventing debris from damaging pumps and components with a tailored filter system, extending equipment lifespan and maintaining coolant purity.

Filters Residual Particles from Cutting Coolant

The QPREP filter systems from QATM are designed to enhance the efficiency and lifespan of metallographic cutting machines by effectively filtering out residual chips and wear particles from coolant systems. These systems feature various mesh sizes to accommodate diverse machine models, ensuring tailored protection and cleaner operation. Ideal for metallic materials, metallographic samples, and precision metal parts, the filters extend the lifespan of cutting machinery by preventing residual contamination. QPREP filter systems integrate seamlessly with both bench-top and floor-standing equipment, supporting manual, automatic, and fully automated operations. Available in various dimensions to fit specific cooling capacities, the systems are perfect for material testing laboratories, R&D centers, and quality control departments. With corrosion-resistant materials and easy maintenance, the QPREP systems provide reliable filtration solutions that contribute to the integrity and quality of the metallographic process.

Benefits

- Extends machinery lifespan by preventing debris buildup in cutting equipment.

- Enhances coolant cleanliness, reducing maintenance frequency and costs.

- Provides customizable filtration options to suit specific machine requirements.

- Supports energy-efficient operations by maintaining optimal equipment performance.

- Easy integration with existing systems for seamless operational flow.

- Applications

- Metal powders, Sample preparation, Metallographic samples, Cutting machines, Metallic materials

- End products

- Metallographic specimen mounts, Titanium alloys, Stainless steel plates, Aluminum sections, Gear components, Precision metal parts, Cast iron sections, Alloy billets, Copper sheets, Metal rods

- Steps before

- Material Preparation, Specimen Mounting, Clamping, Sectioning

- Steps after

- Grinding, Polishing, Etching, Hardness Testing, Sample Analysis

- Input ingredients

- cut-off wheel, specimen chips, cooling water, waste water

- Output ingredients

- residual materials, clean coolant

- Market info

- QATM is renowned for its expertise in manufacturing high-quality metallographic equipment and consumables, providing innovative solutions for material testing and analysis, which are trusted by laboratories and quality control professionals globally.

- Mesh size

- 60 μm / 100 μm / 800 μm / 150 μm

- Filter dimensions

- 490 x 290 x 190 mm / 290 x 150 x 190 mm / 250 x 200 x 155 mm

- Coolant recirculation volume

- 45 Ltr / 15 Ltr

- Filter fleece roll length

- 100 m

- Filter fleece roll width

- 710 mm / 420 mm

- Filter fleece mat dimensions

- 940 x 720 mm / 724 x 720 mm / 235 x 148 mm

- Hanging basket dimensions

- 140 x 80 x 200 mm

- Filter system mesh size

- 60 μm / 100 μm / 800 μm

- Cooling system compatibility

- Recirculating cooling unit

- Filter type

- Belt filter / Filter fleece

- Filter dimensions

- 490 x 290 x 190 mm / 290 x 150 x 190 mm / 250 x 200 x 155 mm

- Cutting machine compatibility

- Brillant 255 / Qcut 400 A / Brillant 270

- System protection level

- Prevents pump and machine damage

- Filter lifespan

- Prolongs coolant cleanliness

- Custom application filter selection

- Based on machine type and usage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Basket Shape

- Hanging

- Basket Material

- Stainless Steel

- Basket Size

- 140 x 80 x 200 mm

- Filter Dimensions

- 490 x 290 x 190 mm

- Mesh Size

- 60 μm/ 100 μm / 800 μm

- Filter Fleece Size

- 940 x 720 mm

- Filter Fleece Material

- Coarse, 150 μm

- Filter mesh size

- 60 μm / 100 μm / 800 μm

- Filter dimension options

- 490 x 290 x 190 mm

- Filter fleece type

- Coarse, 150 μm

- Filter basket material

- Stainless steel

- Integration with cooling systems

- 45 Ltr. recirculating cooling unit

- Applicable machine models

- Brillant 255 / Qcut 400 A