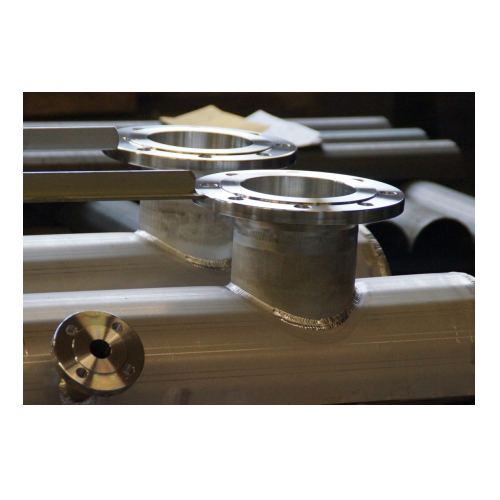

Expert welding assembly for industrial applications

Optimize complex fabrication tasks with precision-engineered welding assemblies, enhancing structural integrity and reliability in high-demand production environments.

Enhances Precision Welding and Assembly Processes

SPALECK’s precision welding assemblies streamline your metal fabrication needs, offering expertly crafted solutions for diverse industries from metal fabrication to food processing. These assemblies utilize robotic welding for consistent quality and efficiency, essential for crafting components like CNC machined gears and structural steel frameworks. They integrate seamlessly into existing production lines, supported by SPALECK’s advanced automation capabilities. Operating under certified standards such as DIN EN ISO 3834-2, these assemblies deliver exceptional precision, ensuring products meet the rigorous demands of industries like recycling and pharmaceuticals. Constructed from high-grade materials for enhanced corrosion resistance, they promise durability and reliability. Designed for ease of maintenance and fully customizable to suit specific requirements, they are your robust partner in achieving high-quality outputs with reduced energy consumption.

Benefits

- Enhances production efficiency with robotic welding, ensuring consistent output and quality.

- Reduces operational costs through energy-efficient processes and automated controls.

- Certified for stringent industry standards, providing reliable compliance and safety assurance.

- Offers customizable solutions to meet specific industrial requirements and integration needs.

- Designed for durability in corrosive environments, extending equipment lifespan and reducing maintenance needs.

- Applications

- Food industry components, Metal assemblies, Recycling materials, Chemical industry components, Sieving machines for food, Surface finishing, Precision parts, Water treatment components, Metal processing, Manufacturing materials, Pharmaceuticals

- End products

- Robotically welded car frames, Chemical-resistant tanks, Custom metal brackets, Recycled aluminum sheets, Fine mesh sieves for flour, Membrane filtration units, Structural steel frameworks, Polished metal panels, Food grade processing trays, Stainless steel pill containers, Cnc machined gears

- Steps before

- Metal Cutting, Forming, Laser Cutting, Bending

- Steps after

- Surface Treatment, Assembly, Quality Inspection, Packaging

- Input ingredients

- Metallteile, Konstruktionsteile, Großaggregate, Kleinteile

- Output ingredients

- Schweißbaugruppen, Präzise Schweißverbindungen, Schweißteile, Komplexe Schweißkonstruktionen

- Market info

- Spaleck is known for its expertise in designing and manufacturing innovative screening, separation, and conveying technology, particularly for recycling and bulk materials industries, and is reputed for high-quality, durable equipment tailored to customer specifications globally.

- Automation

- Manual and Full Robotic Welding

- Material Thickness

- Capability to handle various thicknesses, from small to large parts

- Compliance with Standards

- DIN EN 1090-2 EXC3, DIN EN ISO 3834-2, AD 2000 – Merkblatt HP0, DIN EN 15085-2 CL1 and CL2

- Welding Techniques

- MIG, MAG, WIG, Arc Welding, Resistance Welding, Stud Welding

- Quality Assurance

- ISO 9001

- Production Scale

- Single Parts to Mass Production

- Precision Level

- High-Precision Welding

- Product Types

- Simple to Complex Welded Assemblies

- Automation level

- Manual / Robot welding

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual / Automated cleaning

- Energy efficiency

- High / Low consumption

- Quality assurance

- Made in Germany standards

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- N/A

- Control panel type

- PLC-controlled / HMI

- Integration possibilities

- Roboterschweissen / Automatic systems