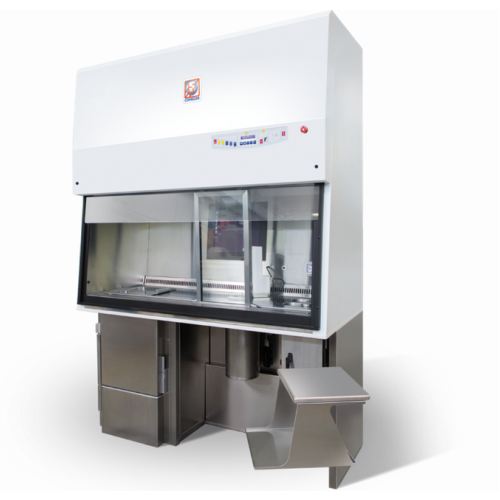

Biohazard hood for radiopharmaceutical preparation

Ensure sterile and safe radiopharmaceutical preparation with a Class A laminar flow hood, optimized for handling sensitive isotopes like Tc99m, ensuring both operator protection and process integrity.

Ensures Sterile Radiopharmaceutical Preparation

The BH Series Biohazard Class A Hood by Comecer is a laminar flow workbench specifically designed for critical radiopharmaceutical applications. It features a spacious work chamber with Class A air quality, providing an ideal environment for sterile Tc99m compound preparation. The hood incorporates a unique shielding system with Pb options from 5 to 50mm, safeguarding operators while handling sensitive isotopes. Integrated systems such as a dose calibrator with monitor support and Mo99/Tc99m generator elution setup streamline the radiopharmaceutical preparation process.

The hood’s ergonomic design includes a sliding shielded glass front and specialized compartments for waste and generator storage, ensuring efficient workflow management. Compliance with EN12469 Class II standards and GMP directives underscores its suitability for rigorous laboratory and production settings. Optional upgrades, including a stainless steel work area and HEPA H14 filtration, enhance its resilience and sterile operation capability. Perfect for pharmaceutical manufacturers and healthcare facilities, this hood offers comprehensive safety and process efficiency in radioactive material handling.

Benefits

- Ensures contamination-free radiopharmaceutical preparation with Class A sterile environment.

- Enhances operator safety with comprehensive shielding for radioisotopes.

- Streamlines workflow with integrated calibration and elution systems.

- Minimizes hazardous waste exposure with dedicated waste management compartments.

- Complies with GMP standards, ensuring seamless integration into regulated environments.

- Applications

- Isotopes, Radiopharmaceuticals, Tc99m compounds, Spect emitters, Nuclear medicine

- End products

- Steps before

- Radionuclide Production, Isotope Preparation, Ingredient Mixing

- Steps after

- Radiopharmaceutical Dispensing, Sterilization, Compounding, Dose Calibration

- Input ingredients

- radioisotopes, Mo99/Tc99m generators, dose calibrator

- Output ingredients

- radiopharmaceuticals, class A air quality

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Shielding Thickness

- Pb 5, 10, 30, or 50mm

- Material Purity

- Pb 98% + Sb 2%

- Work Surface Material

- AISI 304 stainless steel

- Filtration System

- HEPA H14 absolute filtering cartridge

- Air Inflow

- Conforming to reference standards

- Air Outflow Filtration

- HEPA H14 absolute filter

- Compliance

- EN12469 (Class II), Class A cGMP

- Generator Compatibility

- Mo99/Tc99m generators

- Monitor Size

- 17” monitor integration

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- GMP Compliance

- cGMP Class A

- EN12469

- Class II

- Work chamber material

- AISI 304 stainless steel

- Monitor integration size

- 17” monitor

- Shielding thickness

- Pb 5 or 10 or 30 or 50mm

- Shielded glass type

- Sliding shielded glass

- Generator lifting capacity

- 2 Mo99/Tc99m generators

- Controlled work area size

- Spacious work chamber

- Filtration system type

- HEPA H14 absolute filter

- Compartment setups

- Dose calibrator, solid waste, generator

- Shielding Thickness

- Pb 5, 10, 30, or 50mm

- Material

- AISI 304 stainless steel

- Generator Lift System

- Automatic lift for Mo99/Tc99m generators

- Monitor Integration

- 17” monitor for dose calibrator control

- Filtration

- HEPA H14 absolute filtering cartridge

- Airflow

- Laminar flow, downflow system

- Waste Compartment

- Shielded with extraction door outside Class A area

- Control Integration

- PC support and calibrator console set-up