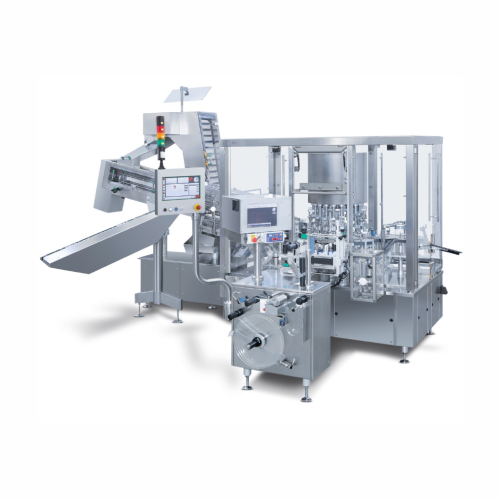

Automatic syringe plungering and labeling system

Optimize your production line with precision syringe handling and labeling that ensures consistent quality and operational efficiency. This solution integrates smoothly, enhancing throughput and reliability for high-demand biopharmaceutical environments.

Assembles and Labels Pharmaceutical Syringes

The COMBI 2 PL from Marchesini Group is an innovative machine tailored for pharmaceutical and biotech companies that require precise syringe assembly and labelling. This continuous motion equipment excels in efficiently handling the assembly of various syringe types, including insulin, heparin, and vaccine syringes. Designed to accommodate up to 24,000 syringes per hour, it ensures high throughput with minimal supervision.

Operating with an automatic syringe loading system, the machine integrates seamlessly into your production line, from plunger insertion to precise labelling and inspection. With features like a PLC-controlled interface and optional vision systems, it offers comprehensive monitoring and control. The ergonomic design allows for easy maintenance, while the fully customizable options ensure compatibility with your specific manufacturing needs. Outfitted for compliance, it meets strict pharmaceutical industry standards, making it an ideal choice for companies focused on producing high-quality, safe medical devices.

Benefits

- Increases production efficiency by handling up to 24,000 syringes per hour.

- Ensures product quality and safety with integrated inspection and sorting systems.

- Reduces labor costs through automated assembly and labelling processes.

- Enhances customization to meet specific production needs with modular component options.

- Maintains regulatory compliance with GMP standards for pharmaceutical manufacturing.

- Applications

- Biopharmaceuticals, Vaccine syringes, Medical devices, Pharmaceutical syringes

- End products

- Insulin syringes, Heparin syringes, Influenza vaccine syringes, Tuberculin syringes, Covid-19 vaccine syringes

- Steps before

- Syringe molding, Component preparation, Material inspection

- Steps after

- Sterilization, Quality control, Packing

- Input ingredients

- syringes, plungers, glass syringes, plastic syringes, label tape

- Output ingredients

- assembled syringes, labelled syringes

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Automation

- Automatic, continuous motion

- Capacity

- Up to 24, 000 syringes/hour

- Plunger assembly control

- Yes

- Label application

- Automatic distribution

- Syringe size compatibility

- 0.5 - 20 ml

- Syringe material

- Glass or plastic

- Screwing unit

- Totally parameterizable

- Operational repeatability

- Perfect

- Installation space

- Minimal

- Positive logic management

- Yes

- Label reel management

- Yes

- "Label applied" control

- Yes

- Product sorting

- Motorized flap sorter

- Error rejection and counting

- Automatic, with external box collection

- Product unloading verification

- Compliant and non-compliant

- Unloading and counting

- Guide or no-contact robotized systems

- Customization options

- Wide choice of optional units

- Working mechanism

- Automatic, continuous motion

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual or automated with optional systems

- Changeover time

- Minimal due to customizable options

- Capacity

- Up to 24, 000 syringes per hour

- Air incorporation control

- Yes

- Syringe size range

- 0.5 to 20 ml

- Label applied control

- Automatic verification

- Error rejection

- Automatic rejection and counting

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- 0.5–20 ml

- Material type

- Glass / Plastic syringes

- Plunger type

- Elevator / Vibrating feeder

- Label application

- Automatic label distribution

- Compact footprint

- Minimal installation space

- Loading method

- Automatic syringe loading on roller conveyor

- Plunger loading method

- Elevator and roller conveyor or vibrating feeder

- Control panel type

- Totally parameterizable screwing unit

- Syringe compatibility

- Glass or plastic syringes

- Syringe size

- 0.5 / 20 ml

- Syringe compatibility

- Glass or Plastic Syringes

- Optional Units

- Vision system, printing systems, feeding systems

- Control Logic

- Positive Logic Management

- Operation Mode

- Automatic, Continuous Motion

- Labeling Integration

- External labelling unit with unwinder, printer lodging, and rewinder