Automatic grinder and polisher for metallographic sample preparation

Easily transition from grinding to polishing with precise control for consistent sample quality, optimizing your metallographic sample preparation process without compromising performance.

Grinds and Polishes Metallographic Samples

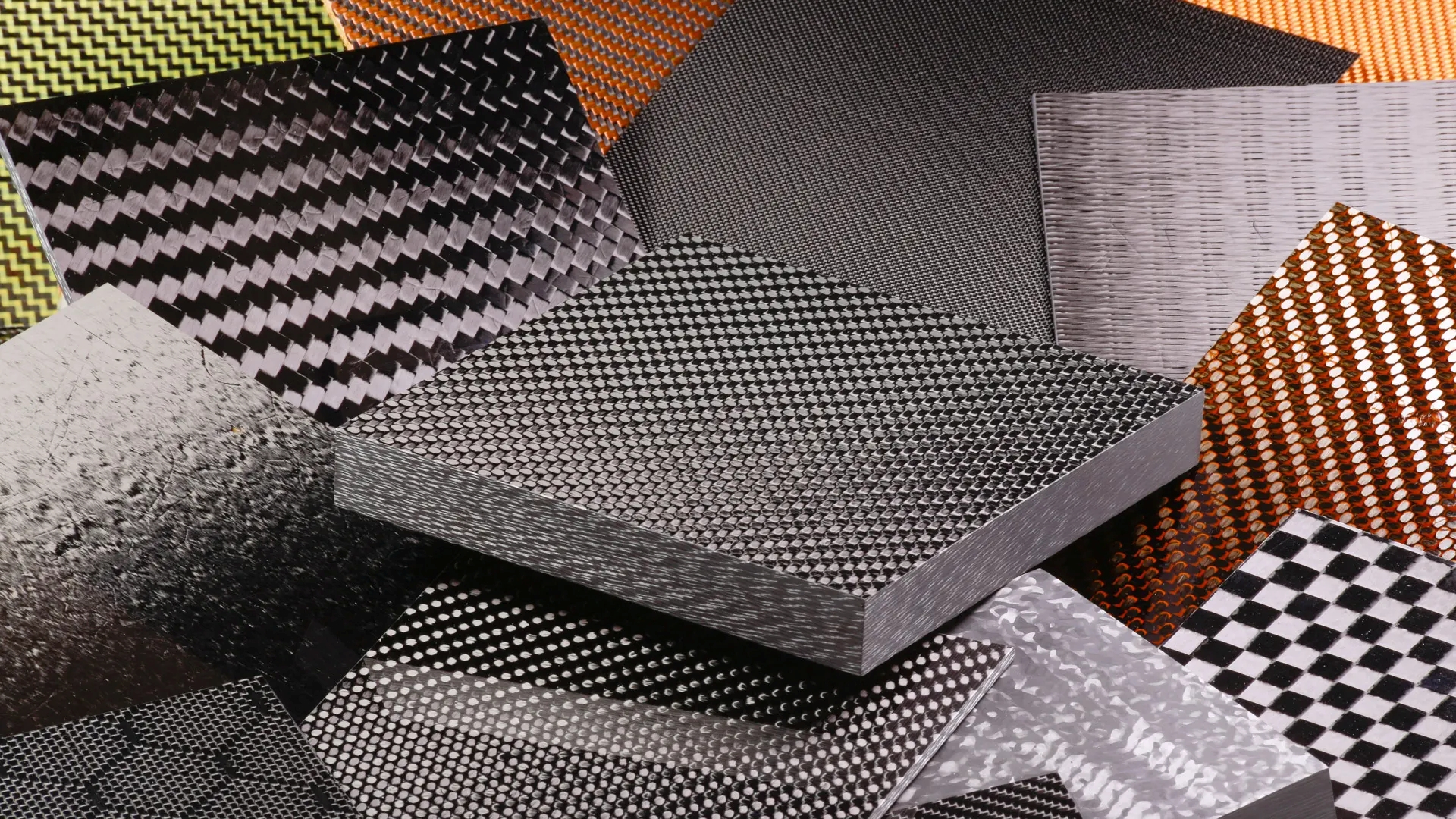

The Qpol 300 A1-ECO+ from ATM Qness GmbH is a versatile single-disc grinder and polisher designed for precise preparation of metallographic samples. This equipment offers the unique ability to store up to 200 customizable preparation methods, ensuring consistent results across a wide range of materials including metal alloys, ceramics, and composites. Operating with a single-disc design, it facilitates efficient cleaning and maintenance, allowing unobstructed access to all components after use. The machine supports both clockwise and counter-clockwise rotations, with variable-speed options for detailed control over grinding and polishing processes. Integration with the optional Qdoser ECO or ECO+ dosing systems enhances flexibility, automating the application of polishing suspensions for increased productivity. With a robust build featuring an impact-proof plastic bowl and powder-coated aluminum case, it is designed for durability and ease of use. Ideal for metallography, material science research, and industrial quality control, the Qpol 300 A1-ECO+ is a key tool in laboratories and manufacturing lines requiring precision material analysis.

Benefits

- Streamlines sample preparation with customizable methods, enhancing operational efficiency.

- Minimizes maintenance time through easy access cleaning features.

- Increases process flexibility with adjustable pressure and rotation settings.

- Enhances productivity with automated dosing system compatibility.

- Ensures consistent results for diverse material types, supporting comprehensive quality control.

- Applications

- Metallurgical qc, Ceramics, Metallographic samples, Geological specimens, Metallic structures, Hard metals, Engineering materials, Metal alloys, Industrial coatings, Composites

- End products

- Qc metallurgical reports, Geological thin sections, Metallic grain structure samples, Hard metal durability samples, Metal alloy test specimens, Industrial coating thickness test samples, Composite material test samples, Engineering component samples, Microstructural analysis samples, Ceramic hardness test pieces

- Steps before

- Cutting, Mounting

- Steps after

- Etching, Hardness Testing

- Input ingredients

- metallographic samples, grinding medium, polishing medium, diamond suspensions, lubricant, final polishing suspensions

- Output ingredients

- prepared metallographic samples, ground and polished samples, polished surfaces

- Market info

- QATM is renowned for its expertise in manufacturing high-quality metallographic equipment and consumables, providing innovative solutions for material testing and analysis, which are trusted by laboratories and quality control professionals globally.

- Working Wheel Diameter

- 250/300 mm

- Touch Screen

- 4.3 inch

- Speed (Grinder)

- 30 - 600 min-1

- Speed (Head)

- 30 - 160 min-1

- Single Pressing Force

- 5-80 N

- Central Pressing Force

- 20-350 N

- Drive Power (Grinder)

- 0.75 kW (S1)

- Drive Power (Head)

- 0.18 kW (S1)

- Connection Power

- 2.8 kVA

- Water Connection

- 1x fresh water connection R½" max. 6 bars

- Automation

- Automatic Grinding/Polishing and optionally automatic dosing

- Automation level

- Manual / Fully Automatic

- Cleaning method

- Manual / Cleaning Boost

- Changeover time

- Quick release mechanism

- Batch vs. continuous operation

- Batch

- Pressure adjustment

- 5 - 350 N

- Direction of rotation

- Clockwise / Counter-clockwise

- Abrasion resistance

- Yes

- Biological compatibility

- No

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High resistance

- Density/particle size

- Varies with sample

- Machine footprint (W x H x D)

- 511 x 530-610 x 710 mm

- Weight

- 64 kg

- Working wheel diameter

- ø 250/300 mm

- Control panel type

- 4.3" touch screen

- Material construction

- Aluminium case, powder coated

- Bowl material

- Impact-proof plastic

- Number of samples (single pressure)

- 1-6 samples ø 50 mm

- Water connection

- 1x fresh water connection R½" max. 6 bars

- Drive power (grinder and head)

- 0.75 kW (grinder), 0.18 kW (head)

- Control panel type

- 4.3" Touch-Screen

- Integration possibilities

- Qdoser ECO / ECO+ / ONE

- Operation mode

- Automatic / Manual

- Sample holder availability

- Standard and Special Design

- Sample preparation methods storage

- 200 Customized Programs