Assembly service for mechanical and electromechanical components

Streamline your production assembly with seamless integration of mechanical and electromechanical components, enhancing efficiency and reducing logistical complexities while ensuring precision and reliability.

Assembles Mechanical and Electromechanical Components

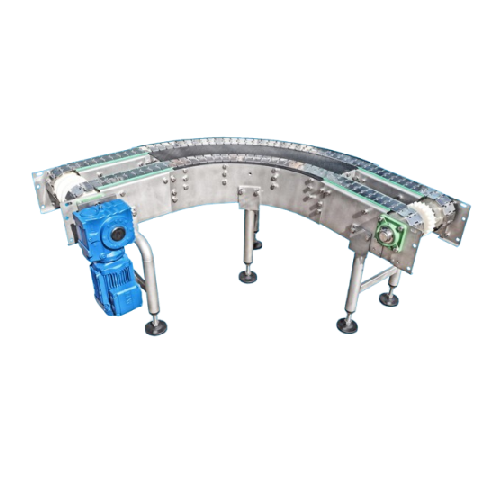

SPALECK offers the Baugruppenmontage solution, expertly designed to streamline the assembly of mechanical and electromechanical components for industries such as pharmaceuticals, machinery manufacturing, and food processing. This equipment supports operations from small batch to large series production, providing flexible assembly and just-in-time logistics management.

Utilizing precision CNC machining and skilled robot welding, this equipment assembles a wide range of components, from automotive engine mounts to pharmaceutical dispensing equipment. Ideal for industrial applications requiring detailed coordination and quality control, it ensures seamless integration into existing production lines.

Baugruppenmontage handles diverse materials, including metals and plastics, and supports custom metalwork components like brackets and precision gears. Its modular design allows for rapid reconfiguration, adapting to changing production demands. Delivering documented quality assurance, this assembly line facilitates compliance with industry standards and certifications.

Additionally, SPALECK provides comprehensive engineering support, accommodating custom requests and optimizing for energy efficiency. Equipped with a PLC-controlled system, it ensures precise operation with remote monitoring capabilities, thereby optimizing assembly workflow and minimizing downtime.

Benefits

- Enhances production efficiency by minimizing lead times with just-in-time assembly.

- Reduces operational costs through optimized coordination and supply chain management.

- Increases production flexibility with modular design for easy reconfiguration.

- Ensures high-quality standards with comprehensive, documented quality control processes.

- Decreases logistical complexity with integrated assembly and installation services.

- Applications

- Cnc machining, Small batch production, Electromechanical assemblies, Component assembly, Industrial components, Automation, Manufacturing equipment, Machinery, Prototyping, Large series production, Mechanical assemblies, Logistics, Metalworking, Pharmaceuticals

- End products

- Hydraulic power units, Industrial conveyor systems, Pneumatic actuators, Electrical control panels, Mass-produced industrial fasteners, Automotive engine mounts, Automated assembly line robotics, Cnc machined aluminum blocks, Custom metal brackets, Small batch custom machinery, Prototype circuit boards, Hvac system components, Precision metal gears, Pharmaceutical dispensing equipment

- Steps before

- Component procurement, Material preparation, Metal fabrication, Laser cutting, CNC machining, Surface finishing

- Steps after

- Quality inspection, Packaging, Labeling, Logistics, Distribution

- Input ingredients

- vorgefertigte Bauteile, mechanische Komponenten, elektrische Komponenten, pneumatische Komponenten, hydraulische Komponenten, Metallverarbeitungsteile, Kunststoffteile, elektronische Komponenten, hydraulische Komponenten, pneumatische Komponenten

- Output ingredients

- Baugruppen, Teilbaugruppe, fertige Systeme, einsatzbereite Systeme

- Market info

- Spaleck is known for its expertise in designing and manufacturing innovative screening, separation, and conveying technology, particularly for recycling and bulk materials industries, and is reputed for high-quality, durable equipment tailored to customer specifications globally.

- Assembly type

- Mechanical, Electrical, Pneumatic, Hydraulic

- Delivery type

- Just in time

- Documentation

- Complete process documentation

- End product

- Fully functional assembly

- Assembly size

- Klein-, Großserien

- Installation

- Inclusive of Electroinstallation

- Production type

- Batch and Continuous

- Supply chain coordination

- From procurement to assembly

- Quality assurance

- Certified with Quality and Functional tests

- Material Handling

- Metallverarbeitung, Kunststoff, Others

- Integration capabilities

- Hydraulic, Pneumatic, Electronic components

- Process optimization

- Expert construction and optimization advice

- Assembly speed

- Fast / Efficient

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Changeover time

- Minimal

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- High / Cost-effective

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Industries served

- Pharmaceutical, Manufacturing

- End-product type

- Complete assemblies

- Machine footprint

- Compact for various installations

- Assembly flexibility

- Supports small to large series

- Modular design

- Customizable components based on need

- Automation integration

- Includes electromechanical assemblies

- Custom build capability

- Accommodates various industrial applications

- Transport efficiency

- Designed for minimal need for additional transport

- Integration possibilities

- Mechanical, electromechanical, electronic, hydraulic, pneumatic

- Customization level

- Prototypes, small series, large series

- Documentation type

- Complete documentation

- Montage line

- Tailored to components

- Service inclusion

- Electrical installation

- Logistics options

- Storage, just in time delivery