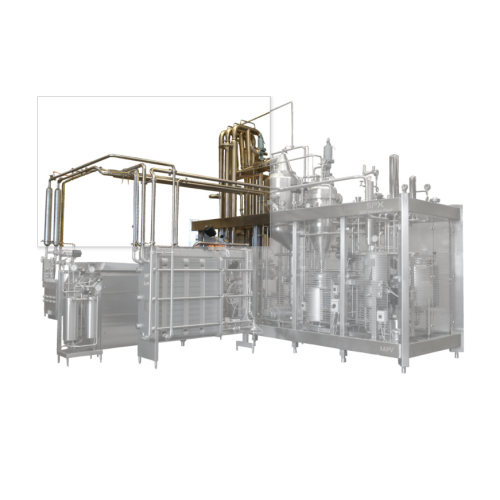

Ultra high temperature (uht) direct heating for infusion Esl plant

In the dairy industry, maintaining freshness and extending shelf life while ensuring product safety are crucial challenges. Traditional pasteurization processes often result in a compromise between quality and shelf life, necessitating advanced techniques for superior results.

Instant heating at ultra-high temperatures.

The Infusion ESL Plant by SPX Flow is a cutting-edge UHT system designed for rapid direct heating and infusion, ensuring extended shelf life of dairy products. This system performs pasteurization at 264°F (129°C) for 0.5 seconds with a rapid heating rate of 1112°F (600°C) per second. It delivers precise holding times and boasts a high bacteria spore kill rate, preserving product quality with minimal chemical changes, resulting in a pasteurized milk flavor. A notable feature of the system is its low fouling rate, which reduces the frequency of clean-in-place (CIP) procedures, thus maximizing operational uptime. The plant is pre-assembled, factory-tested, and operator-friendly. Additionally, it can be designed to meet ASME, PMO, and 3-A standards as per requirements.

Benefits

- Extended shelf life of up to 45 days

- High product quality with minimal chemical change

- Low fouling rates and longer operating times

- High spore kill rate for greater safety

- Pre-assembled and factory-tested for reliability