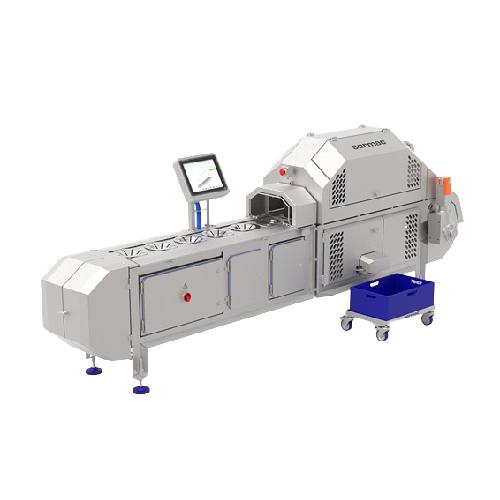

Iceberg lettuce decoring and cutting system

In commercial salad processing, manual decoring of iceberg lettuce can lead to inconsistent results and significant time consumption. Ensuring an efficient and uniform decoring process is crucial to maintaining product quality and optimizing production speed.

Efficiently decore and cut iceberg lettuce

The OptiCor OC-60 by Sormac is a decoring and cutting system specifically designed for iceberg lettuce with diameters ranging from 90 to 220 mm. This system utilizes a camera-based alignment to ensure precise decoring depth, thereby optimizing yield. The core is separated from the end product, enhancing quality. The machine operates on a start-stop principle and can handle up to 60 pieces per minute. Automation options, such as a stepflow singulator and cutting units for segmenting the head into smaller pieces, are available. The OptiCor OC-60 is ideal for salad processing lines and can be combined with other Sormac equipment like the Flume conveyor TF, Salad washer PULSTAR, Centrifuge SC/NextGen, and Air drying tunnel LDT-140.

Benefits

- Precise decoring depth improves yield

- High capacity of up to 60 pieces per minute

- Automated alignment system reduces manual labor

- Segmentation options for flexible processing

- Seamless integration with additional processing equipment