Zoned heating system for thermoformers

Optimize your thermoforming process with precision zoned heating, ensuring uniformity and reducing energy use by 30%, while supporting versatile packaging materials from mono-plastics to multilayer films.

Precisely Heats and Controls Thermoforming Packaging

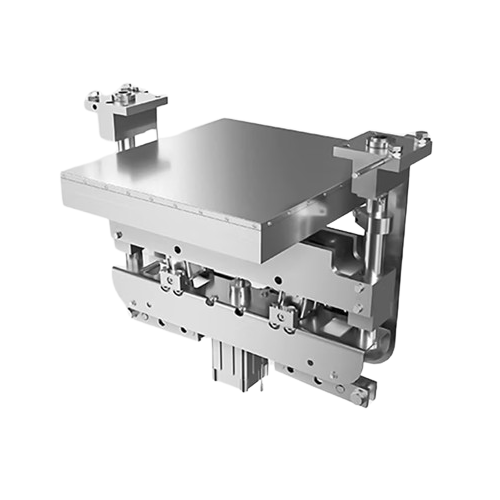

The GEA PowerHeat is an advanced zoned heating system designed to enhance your thermoforming packaging operations. It features ultrathin heating plates with individually controllable zones to ensure precise temperature management across the packaging surface. The system is ideal for producing high-quality end-products such as vacuum-sealed deli meats, MAP-packaged fresh pasta, and mono-material yogurt containers. It operates efficiently in continuous, high-speed, automated settings, boosting productivity by up to 10% and reducing energy consumption by 30% due to its fast reaction time and minimal thermal mass. The GEA PowerHeat supports the use of recyclable mono-plastics and integrates seamlessly within thermoforming packaging systems for food, beverage, and pharmaceutical industries. With precise control tolerances of just 1-2°C, it minimizes the risk of deformations and ensures consistent film quality, making it a critical asset for packaging companies looking to optimize operations and reduce environmental impact.

Benefits

- Increases productivity up to 10% by minimizing setup and cycle times.

- Achieves up to 30% energy savings, reducing operating costs and environmental impact.

- Ensures consistent pack quality with precise temperature control and minimal thermal mass.

- Enhances packaging flexibility using recyclable mono-plastics without compromising integrity.

- Integrates seamlessly into existing lines, improving operational efficiency and scalability.

- Applications

- Map packaging, Mono-plastic packaging, Multi-layer film packaging, Vacuum packaging, Food packaging, Thermoforming packaging

- End products

- Mono-material yogurt containers, Vacuum-sealed deli meats, Map-packaged fresh pasta, Multilayer film sandwich packaging, Sliced cheese packs

- Steps before

- Film selection, Material preparation

- Steps after

- Packing, Sealing, Labelling

- Input ingredients

- mono-material films, multilayer films, plastic

- Output ingredients

- thermoformed packaging, recyclable mono-plastics packaging

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Heating Plate Zones

- Up to 12 zones

- Productivity Increase

- Up to 10%

- Energy Savings

- Up to 30%

- Temperature Control Precision

- ±1-2°C

- Fast Heat-Up

- Minimal thermal mass

- Package Thickness Consistency

- Yes

- Heating zones

- Up to 12 independently controlled zones

- Heating plate thickness

- Ultrathin

- Temperature control precision

- 1-2°C difference

- Thermoforming film compatibility

- Mono-material and multilayer films

- Productivity increase

- Up to 10%

- Energy savings

- Up to 30%

- Heating technology

- Precision heating system

- Processing temperature range

- Narrow for mono-material films

- Reaction time

- Fast

- Environmental impact

- Reduced carbon footprint

- Compatibility with mono-material films

- Yes

- Compatibility with multi-layer films

- Yes

- Recyclable plastics

- Yes

- Impact of precise temperature control

- Minimizes risk of deformations, clouding, and holes

- Heating plate design

- Ultrathin

- Heating zones

- Up to 12 independently controlled

- Footprint

- Compact

- Material type

- Mono- and multilayer films

- Heating plate type

- Ultrathin heating plate