Wire electrical-discharge cutting system

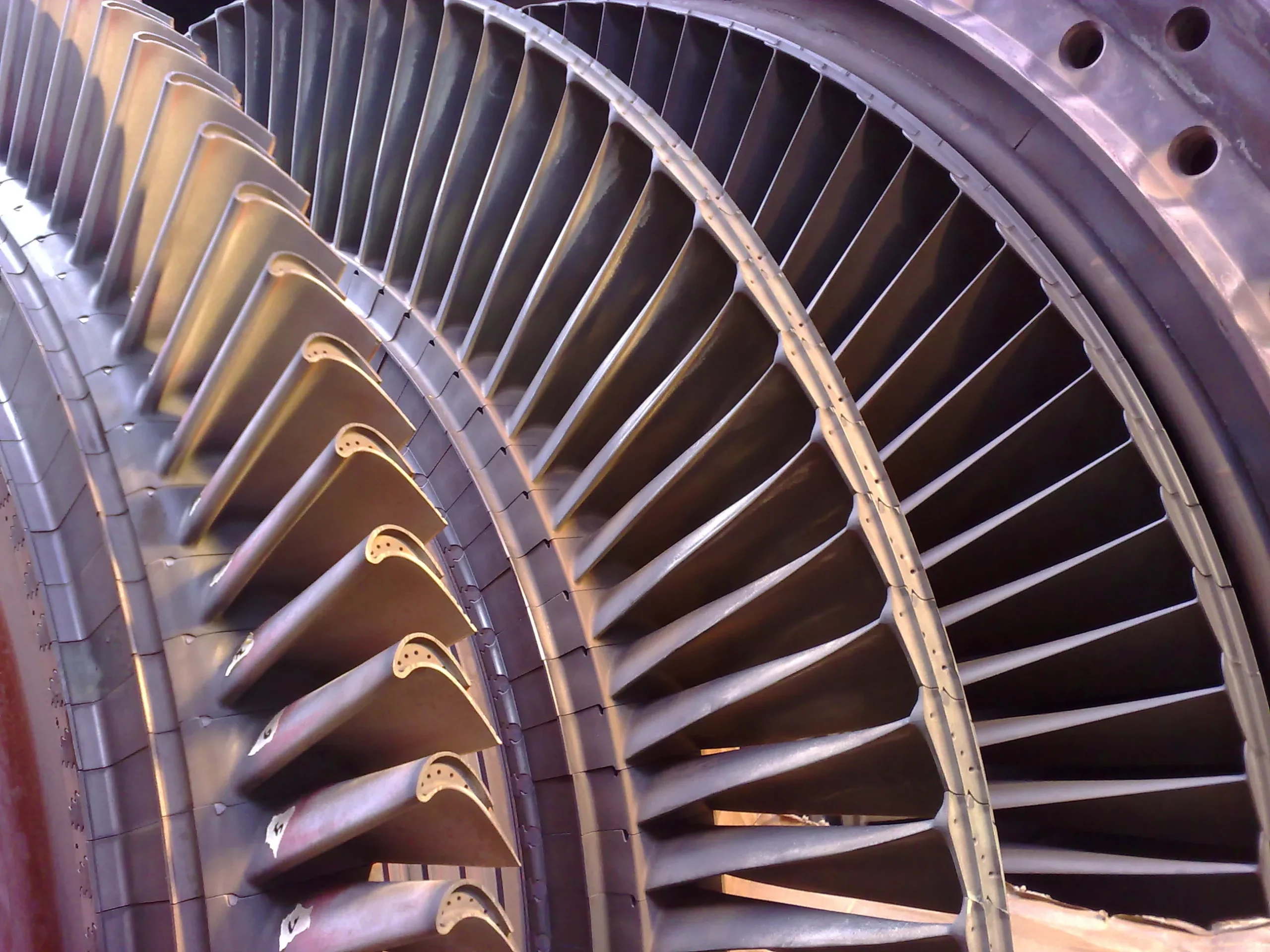

Optimize precision cutting with high reliability, achieving intricate designs and exceptional accuracy for critical components like turbine blades and orthopedic implants. This solution enhances production efficiency with automated real-time monitoring, ensuring consistent quality and minimizing manual interventions in high precision machining operations.

Performs Precision Wire Electrical Discharge Machining

The FANUC ROBOCUT α-CiC series of Wire EDM Machines are engineered to deliver high precision and reliability in manufacturing environments. Specializing in intricate parts, these machines employ a wire electrical discharge machining process that ensures accuracy in creating complex components, such as precision gears and plastic injection mold inserts. The machines cater to a wide range of applications, including aerospace and automotive parts, by slicing through tough materials like metal components with unparalleled precision.

Designed to seamlessly integrate into your production line, these machines feature automated real-time monitoring and AI-driven thermal displacement compensation, enhancing both efficiency and accuracy. The series accommodates different operational needs with model options like the α-C400iC, α-C600iC, and α-C800iB, offering table travels of up to 800mm x 600mm. With the FANUC ROBOCUT-LINKi tool, you can monitor cutting status in real time and swiftly transfer NC programs, optimizing workflow and production management.

Configured for energy efficiency, the series supports a variety of wire diameters and comes with customization options, ensuring adaptability to specific production requirements. The machinery also offers ease of maintenance and complies with industry standards, providing durable performance in high-demand environments.

Benefits

- Enhances production accuracy with AI thermal displacement compensation.

- Minimizes labor costs through automated real-time monitoring and program transfers.

- Adapts to diverse production needs with multiple model options and wire diameters.

- Increases operational efficiency by integrating seamlessly into existing workflows.

- Optimizes energy use, improving overall operational sustainability.

- Applications

- Metal components, Aerospace parts, Tooling and molds, Medical device parts, Industrial machinery parts, Precision components, Electronic components, Automotive parts

- End products

- Punching dies, Plastic injection mold inserts, Precision gears, Circuit connectors, Turbine blades, Orthopedic implants, Injection nozzles, Engine brackets

- Steps before

- Material Preparation, Workpiece Setup, CAD/CAM Programming

- Steps after

- Quality Inspection, Deburring, Finishing, Assembly

- Input ingredients

- electricity, wire, NC programs

- Output ingredients

- high-precision components, cutting status data, production data

- Market info

- FANUC is renowned for its expertise in automation, specializing in manufacturing industrial robots, CNC systems, and machine tools, with a strong reputation for reliability and innovation in industrial automation solutions.

- Model Specific XY axis Table travel

- α-C400iC

- Model Specific UV axis Table travel

- α-C400iC

- Model Specific Z axis Table travel

- 255 mm

- Wire diameter Standard

- φ0.1 - 0.3 mm

- Wire diameter Option

- φ0.05 - 0.3 mm

- Model Specific XY axis Table travel

- α-C600iC

- Model Specific UV axis Table travel

- α-C600iC

- Model Specific Z axis Table travel

- 310 mm

- Model Specific Maximum Allowable Mass of Work Piece

- 40 kg

- Model Specific XY axis Table travel

- α-C800iB

- Model Specific UV axis Table travel

- α-C800iB

- Model Specific Z axis Table travel

- 510 mm

- Indexing accuracy

- 16 sec

- Repeatability

- ±2 sec

- High-speed transfer of NC programs OS

- Microsoft® Windows® 7 / 8 / 8.1 / 10

- Lightweight and compact high precision rotary table Dimensions (L/W/H)

- 170/155/130 mm

- Mass of rotary table

- 16 kg

- Automation level

- PLC / Manual

- Changeover time

- Quick, Simple Start-up

- Cleaning method

- Manual

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Rotary table dimensions

- 170/155/130 mm