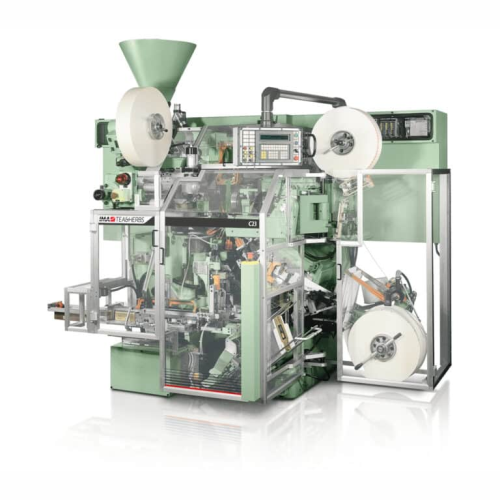

Overhauled tea bag packaging system

Streamline your tea packaging process with this overhauled system, delivering precise, reliable, and customizable non-heatsealable double-chamber tea bags, ensuring seamless integration into your existing production line with increased operational efficiency.

Packages Double-Chamber Tea Bags with String and Tag

The C23 Overhauled from IMA Group is a compact, medium-speed machine designed specifically for the packaging of non-heatsealable double-chamber tea bags with string and folded tag, secured with an aluminium staple. Its standout feature is the ability to integrate knotting technology, replacing staples with knotted threads for improved sustainability. This equipment is ideal for tea and beverage manufacturers requiring precise and efficient packaging processes. With a throughput of up to 220 strokes per minute, the C23 handles a range of tea bag configurations while ensuring reliability and high performance. The machine’s PLC controls and optional integration into existing production lines streamline operations. Additionally, it incorporates an automatic lubrication system and offers full and partial overhaul options utilizing original IMA parts. The C23 is engineered to support environmental standards, with a focus on minimizing production downtime and energy consumption.

Benefits

- Enhances packaging efficiency and precision with its medium-speed, compact design.

- Minimizes production losses with on-site overhaul options and original part replacements.

- Offers sustainable packaging solutions with optional knotting technology, reducing metal use.

- Streamlines integration into existing lines with PLC-controlled operations.

- Lowers maintenance costs and downtime through automatic and centralized lubrication.

- Applications

- Beverages, Packaging products, Tea bags

- End products

- Folded tag tea bags, String-attached tea bags, Tea bags with aluminium staple, Non-heatsealable double-chamber tea bags

- Steps before

- Tea selection, Purification, Drying, Blending, Formulation

- Steps after

- Packing, Cartoning, Case packing, Palletizing, Distribution

- Input ingredients

- tea leaves, filter paper, string, folded tag, aluminium staple

- Output ingredients

- non-heatsealable double-chamber tea bags, tea bags with string and folded tag, tea bags with aluminium staple, knotted thread tea bags

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Machine speed

- Up to 220 strokes/minute

- Tea bag capacity

- Up to approximately 4.0 grams

- Filter bag maximum volume

- 14.26 cubic centimetres

- Total installed power

- 7.5 kW

- Compressed air pressure

- 6 bar

- Compressed air consumption

- 10 Nl/min

- Compressed air inlet

- Ø 3/8 gas

- Machine net weight

- With cartoning attachment max. 3, 250 Kg

- Machine net weight

- With hand removal max 2, 900 Kg

- Lubrication

- Automatic and centralized lubrication system

- Working mechanism

- Double-chamber bag with string, folded tag, aluminium staple

- Machine speed

- Up to 220 strokes/minute

- Automation level

- Manual / Automatic

- Changeover time

- N/A

- Mechanical parts control

- External heat-treatment

- Integration steps

- Complete disassembly, washing, control, and re-assembly

- Lubrication system

- Automatic and centralized

- Upgrade capability

- Knotted thread instead of aluminium staple

- Non-heatsealable compatibility

- Yes

- Tea bag material

- Filter paper

- Aluminium staple compatibility

- Yes

- String material

- Yes

- Knotting thread compatibility

- Yes

- Lubrication material safety

- Automatic and centralized

- Compressed air compatibility

- 6 bar pressure / 10 Nl/min consumption

- Machine parts material

- Original IMA spares

- Bag type

- Double-chamber

- Bag sealing

- Non-heatsealable

- Attachment method

- String, folded tag, aluminium staple

- Machine type

- Overhauled

- Machine footprint

- Compact

- Machine weight

- 2, 900 - 3, 250 kg

- Control panel type

- Updated electrical panel

- Discharge method

- Manual/Automatic

- Machine Configuration

- Modular Components

- Bag Type Option

- Non-heatsealable, double-chamber

- Tagging Method

- Folded Tag with String

- Staple Replacement

- Knotted Thread Integration

- Control Panel Type

- Updated Electrical Panel

- Lubrication System

- Automatic Centralized

- Integration Possibility

- Knotting Technology