Industrial chamber furnace for heat treatment

Maximize efficiency in heat treatment processes with precise temperature control and advanced programmable features, ideal for achieving high-performance outcomes in complex metal and ceramic component production.

Performs Heat Treatment and Sintering Efficiently

The LCF 12/560 from Carbolite Gero represents a robust industrial chamber furnace, ideal for high-temperature applications such as steel and alloy heat treatment, ceramics sintering, and aerospace component production. Engineered for precision, it offers programmable controls and over-temperature protection, ensuring exceptional uniformity and control during critical processes like annealing and alloy treatment. This furnace is capable of reaching maximum temperatures of 1200°C and 1400°C, using either heavy gauge wire or high-quality silicon carbide elements, respectively. Built with energy efficiency in mind, its low thermal mass insulation reduces energy consumption significantly. Designed for integration into complex production lines, the furnace features Ethernet communication for seamless remote monitoring capabilities. Compliant with AMS2750F for aerospace standards, it also offers customization options such as sophisticated digital controllers and bespoke modifications to meet specific operational needs. Additionally, its user-friendly design incorporates a safety door interlock and robust construction to enhance durability and safety in demanding industrial environments.

Benefits

- Enhances process precision with programmable control, ensuring consistent quality in heat treatment outcomes.

- Reduces energy costs through low thermal mass insulation and efficient heating elements.

- Increases operational safety and minimizes risks with door interlock systems and robust construction.

- Facilitates compliance with aerospace standards, supporting AMS2750F requirements for critical applications.

- Offers flexibility and adaptability to specific production needs with customizable chamber sizes and control options.

- Applications

- Metal components, Ceramics, Steels, Aerospace components, Alloys

- End products

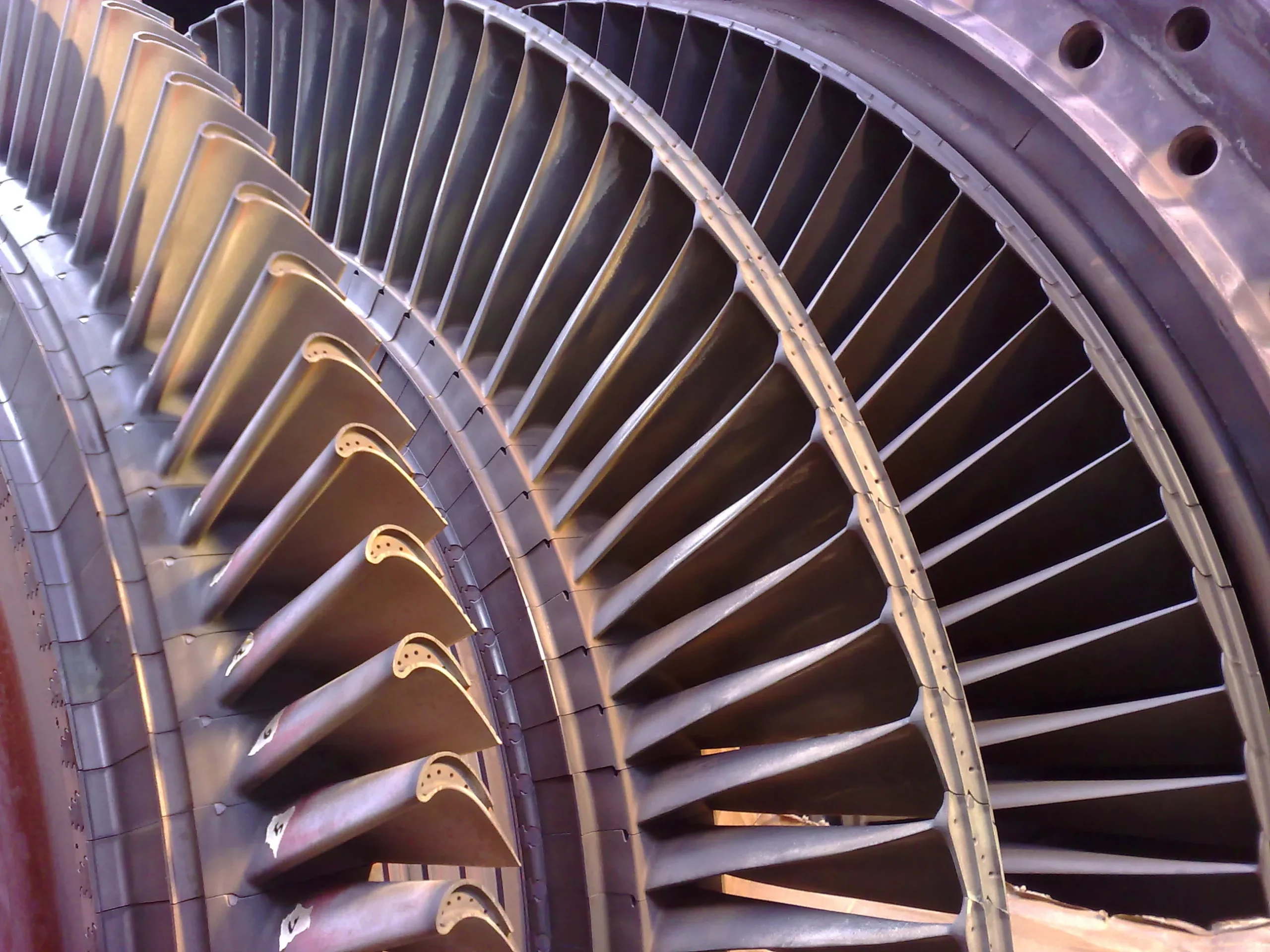

- High-strength alloy wheels, Titanium aircraft fittings, Zirconia ceramic tiles, Tool steel components, Turbine blades

- Steps before

- Casting, Forging, Machining, Preheating

- Steps after

- Quenching, Tempering, Aging, Polishing

- Input ingredients

- steels, alloy, ceramics

- Output ingredients

- heat-treated steels, alloy heat treatment, sintered ceramics

- Market info

- Carbolite Gero is renowned for designing and manufacturing high-temperature laboratory and industrial furnaces and ovens, offering expertise in heat treatment solutions, with a reputation for quality, reliability, and precise thermal processing across various industries.

- Maximum Temperature

- 1200°C, 1400°C

- Controller Type

- Programmable EPC3016P1

- Over-temperature Protection

- Yes

- Construction Material

- Hollow steel section, zinc coated steel sheet

- Insulation Type

- Low thermal mass insulation

- Heating Element

- Heavy gauge wire elements (1200°C), Silicon carbide elements (1400°C)

- Safety Door Interlock

- Yes

- Communication Interface

- Ethernet

- Operating Door

- Manually operated vertically opening door

- Control Options

- Range of digital controllers, multisegment programmers, data loggers

- Pneumatic/Electrical Door Option

- Yes

- Maximum operating temperature

- 1200°C / 1400°C

- Control system

- Programmable EPC3016P1 controller

- Door operation

- Manually operated vertically opening door

- Insulation type

- Low thermal mass insulation

- Heating elements

- Heavy gauge wire elements / Silicon carbide elements

- Safety features

- Safety door interlock

- Communication

- Ethernet

- Automation level

- Manual to full automation

- Customisation options

- AMS 2750F (Nadcap) compliance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Maximum Temperature

- 1200°C, 1400°C

- Construction Material

- Hollow steel section, zinc coated steel sheet

- Door Type

- Manually operated vertically opening door

- Heater Element Type

- Heavy gauge wire and silicon carbide elements

- Insulation Type

- Low thermal mass insulation

- Outer Case Temperature

- Safe due to double skin construction

- Hearth Material

- Silicon carbide tiled hearth

- Chamber Size

- Customizable size available

- Door Operation

- Pneumatically or electrically operated

- Control Systems

- Sophisticated digital controllers, multisegment programmers

- Data Logging

- With digital communication options

- Door Operation

- Pneumatically or electrically operated doors

- Retorts for Atmospheres

- Up to 1000°C

- Remote Control Module

- Available

- Bespoke Specifications

- AMS2750F (Nadcap) compliant