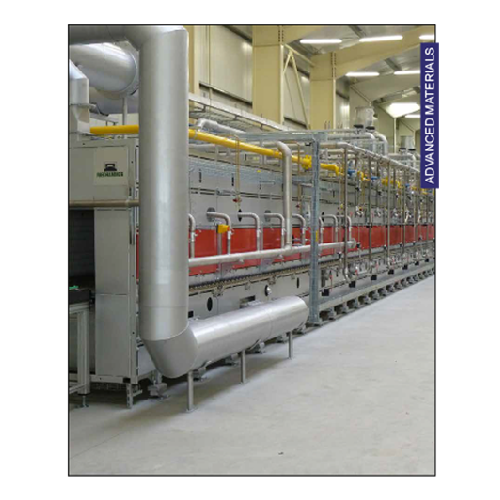

High-temperature kiln solutions for technical ceramics

Achieve precise temperature control up to 1800°C with our versatile kiln solutions, ensuring optimal firing, sintering, and thermal treatment for a wide range of ceramics and advanced materials.

Processes Thermal Treatment for Ceramics and Advanced Materials

The kiln solutions designed by SACMI offer cutting-edge thermal treatment capabilities tailored for the ceramics and advanced materials industries. These kilns stand out with their ability to achieve uniform temperatures up to 1800°C, making them ideal for processing alumina substrates, silicon carbide plates, and other high-performance ceramics. Employing both continuous and batch type kilns, the systems accommodate diverse production needs from high-strength clay bricks to electro-ceramics like piezoelectric sensors and ferrite cores. They ensure precise control in debindering and sintering processes, enhancing product quality and consistency. Available with robust energy efficiency designs, these kilns feature options for stainless steel construction, ensuring resistance to corrosion and longevity. Integration into your production line is streamlined with PLC-controlled operation and remote monitoring capabilities, facilitating seamless automation. Certified to meet industry standards, SACMI kilns also offer customizable specifications to meet your unique process requirements, backed by comprehensive engineering support.

Benefits

- Enhances production efficiency by optimizing thermal processes for superior material properties.

- Maintains precise temperature consistency, improving product quality and yield.

- Reduces energy usage with advanced motor control, leading to lower operational costs.

- Integrates seamlessly into existing lines with scalable automation and remote monitoring.

- Customizable configurations ensure compatibility with a wide range of ceramic and material applications.

- Applications

- Electro-ceramics products, Structural ceramics, Functional ceramics, Bulk materials, Technical ceramics

- End products

- Silicon carbide plates, Zirconia tiles, High-strength clay bricks, Piezoelectric sensors, Capacitor ceramic parts, Porcelain insulators, Ferrite cores, Alumina substrates

- Steps before

- Grinding, Debindering

- Steps after

- Sintering, Coating

- Input ingredients

- structural ceramics, functional ceramics, bulk materials, electro-ceramics products

- Output ingredients

- fired structural ceramics, fired functional ceramics, fired bulk materials, fired electro-ceramics products

- Market info

- Sacmi is renowned for manufacturing advanced industrial equipment, primarily focusing on ceramics, packaging, and food processing. With a commitment to innovation and quality, Sacmi is a market leader in providing engineered-to-order solutions across various sectors.

- Maximum temperature

- 1800°C

- Type of kiln

- Continuous / Batch

- Temperature uniformity

- Excellent

- Atmosphere uniformity

- Excellent

- Process capability

- Debindering / Sintering

- Temperature Range

- Up to 1800°C

- Batch vs. Continuous Operation

- Continuous Kilns / Batch Type Kilns

- Temperature and Atmosphere Uniformity

- Excellent

- Thermal Treatment

- Debindering and Sintering Processes

- Customization

- Specific Firing Technologies for Product Applications

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product compatibility

- Technical ceramics, structural ceramics, functional ceramics, electro-ceramics

- Maximum Temperature

- 1800°C

- Kiln Type

- Continuous / Batch

- Footprint

- Customizable

- Atmosphere Uniformity

- Excellent

- Shape

- Custom solutions

- Continuous or batch type

- Continuous kilns / Batch type kilns

- Temperature range

- Up to 1800°C

- Application type

- Structural ceramics / Functional ceramics / Electro-ceramics

- Integration possibilities

- For structural / functional / electro-ceramics production