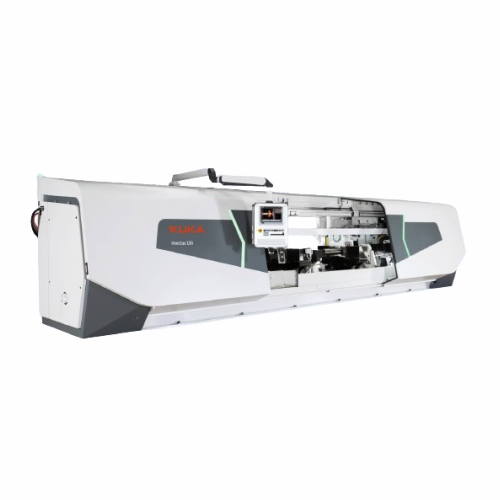

Friction welding system for large industrial components

Achieve high-precision, robust welds for demanding components with our advanced friction welding system, designed to handle large cross-sections and high torque applications, seamlessly integrating into your automated production line for enhanced performance and efficiency.

Performs Precision Rotary Friction Welding

The KUKA Invictus 150 is a versatile rotary friction welding machine designed to meet demanding industry needs, particularly in automotive and oil & gas sectors. It employs a dynamic high-speed spindle and precise process control to join materials like steel and copper-aluminum alloy, delivering superior weld integrity for axle shafts, drive shafts, and hydraulic cylinders. This machine supports automated integration with front or rear loading via robots or gantry systems, enhancing line efficiency and worker safety. It offers customizable configurations, including a Viper Drive system for simulating inertia processes, and a data matrix code interface for seamless Industry 4.0 component tracking. Engineered for durability, the Invictus 150 boasts central lubrication to minimize maintenance downtime and maximize machine reliability.

Benefits

- Enhances production efficiency with rapid, precise welding for large components.

- Reduces maintenance costs through durable construction and central lubrication.

- Facilitates seamless integration with automated loading systems for improved workflow.

- Increases process transparency and quality control via comprehensive data analytics.

- Supports Industry 4.0 connectivity for enhanced productivity and predictive maintenance.

- Applications

- Automotive components, Construction machinery parts, Gas equipment, Oil, Electronics components, Mechanical engineering tools

- End products

- Pipe connectors, Axle shafts, Drive shafts, Copper-aluminum contacts, Hydraulic cylinders, Printing rollers, Engine pistons, Cable lugs, Hydraulic piston rods, Printing cylinders, Drill pipes, Pump shafts, Shut-off valves, Crankshafts

- Steps before

- Component preparation, Facing, Turning

- Steps after

- Flash removal, Quality monitoring, Data analysis, Component tracking

- Input ingredients

- axles, drive shafts, engine pistons, crankshafts, hydraulic piston rods, hydraulic cylinders, rollers, printing cylinders, printing rollers, shafts, spindles, tools, valves, turbo rotor wheels, drill rods, drill pipes, pipe connectors, pump shafts, shut-off valves, rod anodes, aluminum-copper contacts, cable lugs

- Output ingredients

- joined components, welded parts, assembled products, finished components, welded joints

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Forge Force

- 800 – 1500 kN

- Spindle Speed

- Up to 80% higher

- Component Length Capacity

- Up to 3, 900 mm

- Component Diameter Capacity

- Up to 240 mm

- Clamping System

- Automatic / Proportional Control

- Data Interface

- OPC UA

- Automation Interface

- For Robots / Line Integration

- User Interface

- Touch Panel

- Quality Monitoring

- Numerical and Graphical

- Data Export

- USB / Printer / PDF

- Process Control Speed

- 1 ms range

- Temperature Control

- Automatic

- Component Tracking

- Data Matrix Code

- Program Management

- Up to 1, 000 Programs

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Changeover time

- Seamless exchange

- Cleaning method

- Manual

- Energy efficiency

- High spindle speed reduces energy consumption

- Flexible application

- Customizable machine configuration

- Installation

- Crane and truck transport

- Simple cell automation

- Front or rear loading

- Industry 4.0

- Fully monitored machine condition

- Steel

- Yes

- Mixed-material combinations (e.g.,Copper/Aluminum)

- Yes

- Alloy components

- Yes

- Hydraulic components

- Yes

- Large weld cross-sections

- Yes

- Copper/Aluminum materials

- Yes

- Automotive components (crankshafts,axles)

- Yes

- Materials Joined

- Steel and mixed-material combinations

- Component Preparation

- Facing and turning

- Welding Applications

- Automotive, Construction, Mechanical, Oil, Gas, Electronics

- Forge Force

- 800 – 1500 kN

- Spindle Bore Diameter

- up to 240 mm

- Workspace Length

- up to 3, 900 mm

- Machine Bed

- Optimized for stiffness

- Headstock

- Unique bearing technology

- Machine Integration

- Plug, play

- Transport-friendly Design

- Lifting and transporting without removing enclosure elements

- Control Panel Type

- Touch screen operation

- Modularization Approach

- Systematic modularization

- Component Clamping

- Automatic and proportional control

- Control panel type

- Touch screen with HMI

- Integration possibilities

- Plug, play, OPC UA interface

- Machine configuration

- Customized

- Installation

- Cranes and trucks

- Automation interface

- Robots or gantry solutions

- User interface

- Intuitive touch panel with HMI