Friction welding solution for diverse industries

Enhance your production line with friction welding technology that ensures robust, high-precision joints for components ranging from drive shafts to robotic arms, seamlessly integrating with your existing operations to maximize efficiency and quality.

Joins Metallic Components via Friction Welding

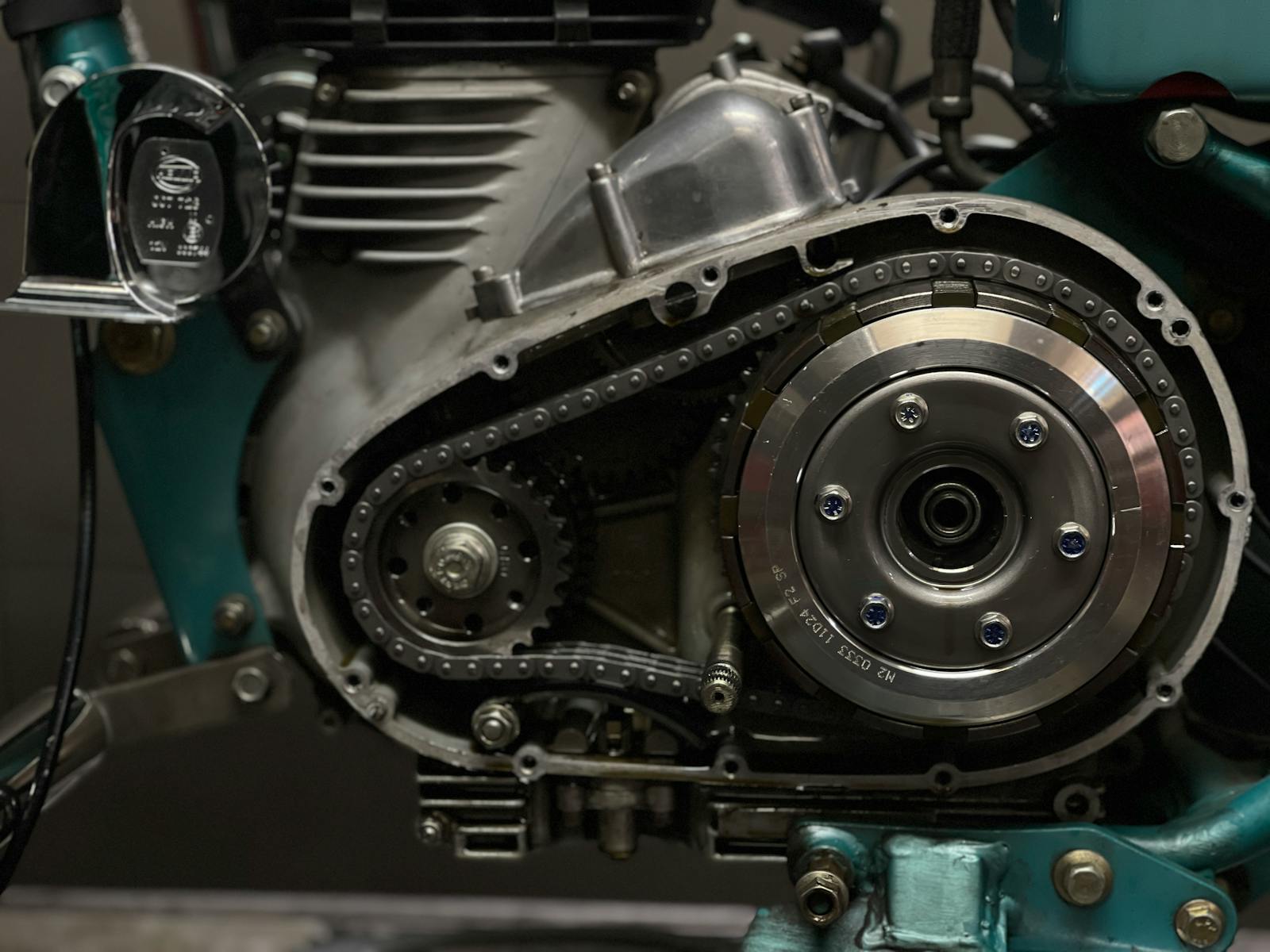

The KUKA Genius series, offered by KUKA AG, consists of innovative friction welding machines designed to address complex joining challenges in various industries. This unique line of equipment utilizes precise friction welding technology to create durable joints in metal components, making it essential for applications in the automotive, aerospace, and energy sectors. The machines offer flexibility with models like the KUKA Genius V and KUKA Genius D, adapting to specific production needs such as vertical installation or double-head configurations for dual welds in one cycle.

These machines are highly automated, featuring PLC control systems and integrated sensors for real-time monitoring, enhancing process efficiency and ensuring superior joint quality. Despite their compact footprint, they boast a wide range of equipment variants to accommodate different component sizes and welding demands, all while maintaining ease of installation and minimal maintenance requirements.

They facilitate an uninterrupted production flow with advanced process monitoring and data backup capabilities, while their sturdy construction with wear-resistant components ensures longevity and reliability. Operators benefit from ergonomic design elements like intuitive touch panels and configurable operation parameters, simplifying setup and maintenance. Tailored solutions and engineering support are available, further optimizing them for specific industrial tasks.

Benefits

- Enhances production efficiency with seamless integration into automated lines.

- Minimizes operational costs via compact design and efficient material usage.

- Increases component durability through precise welding technology.

- Facilitates versatile application across industries with customizable configurations.

- Ensures continuous operation with robust, low-maintenance construction.

- Applications

- Metal components, Automotive components, Marine components, Robotics components, Energy sector components, Agricultural machinery, Manufacturing equipment, Heavy machinery, Aerospace components, Construction equipment, Industrial machinery parts, Structural components

- End products

- Wind turbine hubs, Drive shafts, Hydraulic cylinders, Aerospace brackets, Engine components, Transmission shafts, Robotic arm components, Excavator booms, Agricultural plowshares, Ship propellers

- Steps before

- Component Preparation, Material Selection, Design Verification, Production Planning

- Steps after

- Quality Inspection, Data Documentation, Component Assembly, Logistics and Shipping

- Input ingredients

- different materials, same materials, components, welding tasks

- Output ingredients

- friction welded components, double welds, one-pass productivity, welded parts

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Forge Force

- 12 – 300 kN

- Footprint

- 5.9 – 12 m²

- Speed/Load Range

- Very large range

- Machine Design

- Horizontal/Vertical

- Drive Type

- Direct drive

- Operating Control

- Touch panel with GUI

- Maintenance Interval

- Long lubrication intervals

- Energy Efficiency

- Plug, Play installation

- Cycle Time Reduction

- Extremely short with light curtain

- Automation Ready

- Prepped for automation

- Parameter Control

- Millisecond range monitoring

- Weld Data Documentation

- Database, PDF, Printer Export

- Program Capacity

- Up to 1, 000 welding programs

- Component Traceability

- Data matrix code

- Component Size Compatibility

- Wide range

- Installation Ease

- Simple with no external cabinets

- Working Mechanism

- Friction Welding

- Integration Capability

- Industrie 4.0

- Automation Level

- Plug, Play, Ready for Automation

- Changeover Time

- Minimal

- Space Requirement

- 12 m² or 5.9 m² (vertical model)

- Modular Design

- Yes

- Ergonomic Control

- Touch Screen Interface

- Cycle Time

- Extremely Short

- Energy Efficiency

- High

- Maintenance Method

- Minimal with Long Lubrication Intervals

- Safety Features

- Integrated Light Curtain

- Custom-tailored Solutions

- Yes

- Data Transparency

- Cloud-based, Evaluation via Standardized Interfaces

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Red Dot Design Award

- 2015, 2017

- German Design Award

- Special 2016

- Industrie 4.0 Innovation Award

- 2017

- Machine Footprint

- 12 m²

- Compact Footprint

- 5.9 m² (without control cabinet 4.2 m²)

- Design Configuration

- Horizontal/Vertical

- Head Type

- Single-head/Double-head

- Automatic Operator Door

- Yes

- Operator Control

- Intuitive touch panel

- Drive,Equipment Variants

- Multiple

- Light Curtain

- Integrated (Horizontal Machines)

- Swarf Conveyor

- Side or rear

- Platform

- Modular

- Control panel type

- Touch screen with graphical user interface

- Integration possibilities

- OPC UA data interface, IO-Link

- Design variants

- Single-head or double-head, horizontal or vertical

- Equipment variants

- eco, plus, power

- Space requirement

- Compact footprint, 5.9 m² including control cabinet

- Automation readiness

- Ready for automation, integrated light curtain