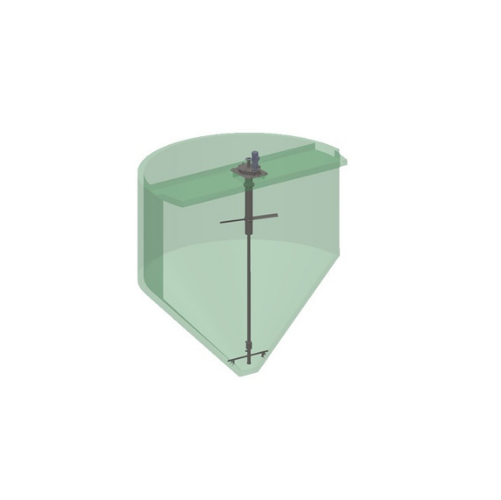

Circular grit separator for wastewater treatment

Efficiently separates grit from wastewater, enabling clean discharge and reducing maintenance issues downstream. Ideal for consistent water treatment performance in your facility.

Efficiently Removes Grit from Wastewater

The Circular Grit Trap DSP from WAMGROUP is designed for efficient grit removal in municipal and industrial wastewater treatment. It operates with a central bearing and two steel blades driven by an impeller, enabling sand to settle while ensuring separation efficiency even with high flow rates. The DSP uses a circular motion to direct sediments to the tank bottom, where a central air lift pipe, powered by compressed air, raises the sand-water mixture for extraction.

Ideal for applications in municipal facilities, industrial plants, and specific industries like fruit and vegetable processing and tanneries, this system effectively processes diverse wastewater types. With the flexibility to fit tanks up to 6 meters in diameter and options for carbon steel or stainless-steel construction, it ensures durability and resistance to corrosive environments.

Installation in existing tanks is straightforward due to its modular design. Low maintenance requirements and robust construction make the DSP a cost-effective solution for continuous operations. Customizable with alternative voltage, frequency, and motor protection levels, it can integrate seamlessly with your facilities’ existing infrastructure.

Benefits

- Enhances process efficiency by reducing grit-related blockages and wear in downstream equipment.

- Lowers operational costs through minimal maintenance needs and durable construction.

- Adapts to various setups with easy installation in existing infrastructure.

- Offers corrosion resistance, ensuring longevity in aggressive wastewater environments.

- Supports diverse treatment applications, from municipal to industrial, broadening its usability.

- Applications

- Vegetable processing waste water, Industrial wastewater, Animal by-products handling, Processing, Sludge treatment, Municipal wastewater, Clean water treatment, Dyeing works waste water, Tanneries, Fruit

- End products

- Tannery effluent, Treated wastewater from vegetable processing, Treated sludge, Treated municipal water, Processed animal by-products, Potable water, Treated wastewater from fruit processing, Treated industrial water, Dyeing effluent

- Steps before

- Screening, Initial Sedimentation, Primary Treatment

- Steps after

- Secondary Treatment, Sludge Treatment, Clean Water Discharge

- Input ingredients

- sewage, wastewater, sand-water mixture

- Output ingredients

- grit, sand

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Tank Diameter

- Up to 6 meters

- Material

- Carbon steel hot dip-galvanised / 304 L / 316 L SS

- Automation

- Drive unit with impeller

- Separation Method

- Air lift with hydro-extractor

- Installation Compatibility

- Easy installation in existing tanks

- Voltage Option

- Alternative voltage and frequency available

- Motor Protection

- Alternative degree available

- Working mechanism

- Tangential sewage entry, circular movement

- Integrated steps

- Grit separation, sand settling, air lift extraction

- Energy efficiency

- Efficient sand-water mixture handling

- Automation level

- Automated drive unit

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Abrasion resistance

- Yes

- Biological compatibility

- Suitable for wastewater

- Cleanability

- Easy clean surfaces

- Corrosive resistance (e.g. acids)

- 304 L / 316 L SS

- Density/particle size

- Suitable for sand

- Tank size

- Up to 6 metre diameter

- Material type

- Carbon steel hot dip-galvanised / 304 L / 316 L SS

- Drive unit

- Central bearing with two steel blades

- Feed method

- Tangential entry into the tank

- Discharge method

- Air lift with hydro-extractor

- Control panel

- Optional

- Motor protection degree

- Alternative options available

- Walkway material

- Hot dip-galvanised carbon steel / 304 L / 316 L SS

- Voltage and frequency

- Alternative options available