Autonomous mobile cobot for warehouse logistics

Streamline your logistics processes with a flexible and fast-moving solution designed to handle complex material transport and palletizing tasks seamlessly, even in demanding cleanroom environments.

Autonomously Transports and Handles Materials

The KMR iisy from KUKA is an autonomous mobile robot that redefines flexibility in industrial environments. It integrates seamlessly into your production processes, offering versatile applications in warehouse logistics, electronics, and semiconductor industries. The KMR iisy supports automated material transport, palletizing, and machine tending tasks, enhancing productivity in handling electronic components, semiconductors, and production workpieces. Its differential drive and intuitive teach pendant control allow precise navigation and operation in diverse settings, including cleanrooms. Equipped with safety scanners and 3D cameras, it ensures high safety standards and collision prevention. This collaborative AMR supports Industry 4.0 with 24/7 operations and remote monitoring, allowing easy maintenance through accessible platform components and IP54 protection for reliability in demanding conditions. Inductive charging pads enable continuous operation, while compliance with ESD standards ensures suitability for sensitive environments. Designed for customizable integration, the KMR iisy boosts efficiency and adaptability, catering to the needs of automotive, electronics, and industrial automation companies.

Benefits

- Enhances operational efficiency with autonomous navigation and precise material handling.

- Reduces labor costs by enabling continuous 24/7 operation with automated processes.

- Ensures safety with collision protection through advanced sensors and 3D cameras.

- Supports flexible production schedules by quickly adapting to different tasks and workstations.

- Maintains cleanroom standards with low particle emissions and ESD certification.

- Applications

- Semiconductor industry, Material transport, Warehouse logistics, Palletizing, Electronics industry, Workpiece transport, Production logistics, Machine tending

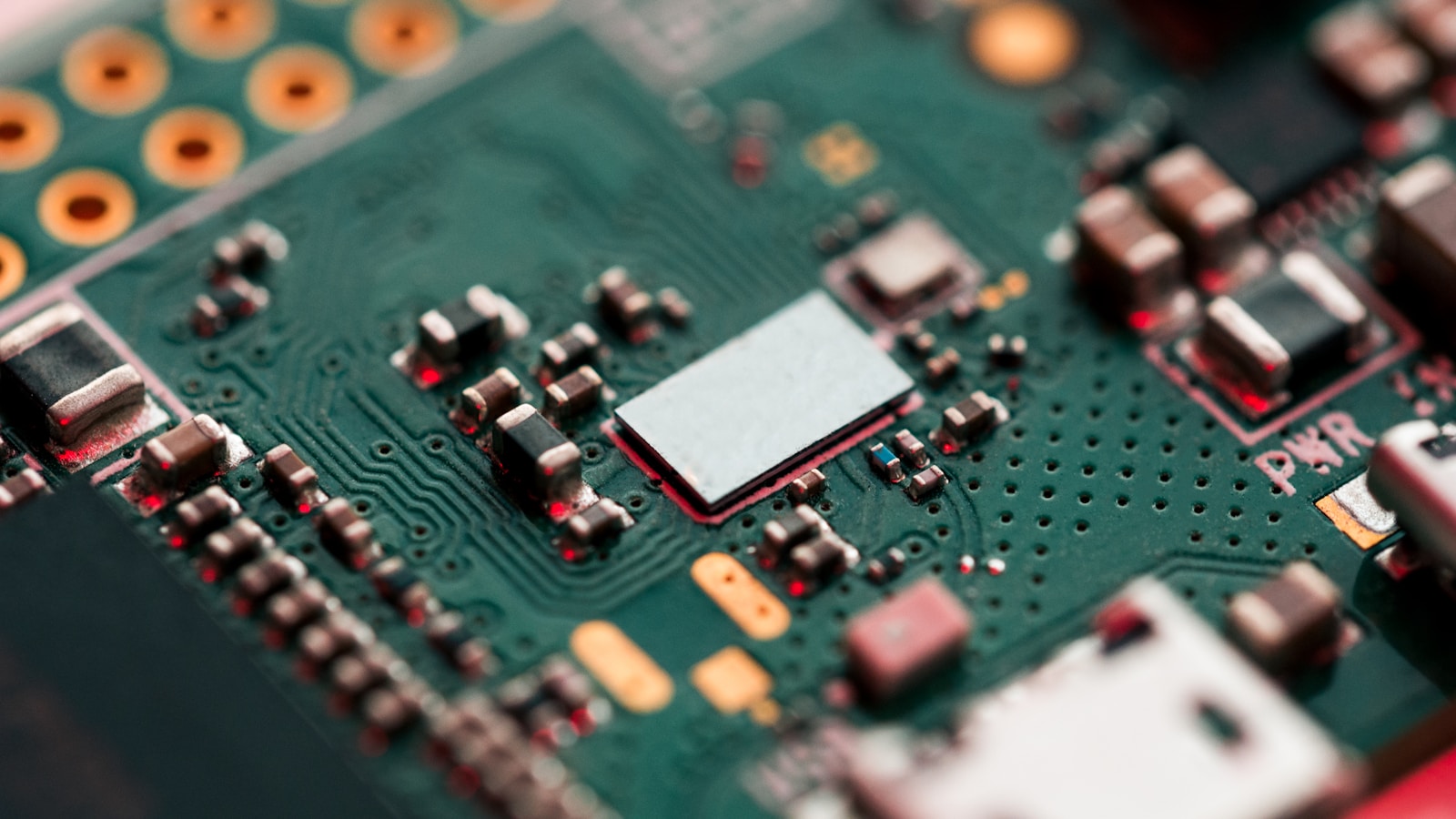

- End products

- Electronic chips, Circuit boards, Product pallets, Packaged materials, Palletized goods, Production workpieces, Semiconductors, Machined parts, Transport crates, Electronic components

- Steps before

- Logistics Planning, Material Staging, Workpiece Preparation

- Steps after

- Quality Testing, Palletizing, Workpiece Handling, Material Delivery

- Input ingredients

- goods, empty containers, components, materials, products

- Output ingredients

- staged goods, loaded tooling, loaded CNC machines, palletized products, transported products, unloaded pallets, removed empty containers

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Load capacity cobot

- 11 kg or 15 kg

- Mobile platform capacity

- Up to 200 kg

- Size of platform area

- 695 × 1120 mm

- Max. speed

- 1.5 m/s

- Navigation

- Slam

- Battery type

- Lithium-ion battery

- Protection class

- IP 54

- Cleanroom class

- 3

- ESD protection

- ISO 61340-5-1 / ANSI ESD S20.20

- International certification

- ICE, UL, FCC

- Operation time

- 24/7

- Automation level

- Autonomous

- Navigation method

- SLAM (Simultaneous Localization and Mapping)

- Collision avoidance

- Yes, safety scanners and 3D cameras

- Changeover time

- Rapid, flexible task switching

- Continuous operation

- 24/7 capability with inductive charging

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ESD certification

- ISO 61340-5-1 and ANSI ESD S20.20

- Cleanroom compatibility

- Class 3

- Applications

- Pick-and-place, palletizing, material transport

- ESD certification

- ISO 61340-5-1 / ANSI ESD S20.20

- International Certification

- CE / UL / FCC / ICE

- Control panel type

- smartPAD pro

- Platform size

- 695 × 1120 mm

- Load capacity cobot

- 11 kg or 15 kg

- Mobile platform capacity

- up to 200 kg

- Max. speed

- 1.5 m/s

- Control panel type

- smartPAD pro

- Integration type

- Single teach pendant

- Navigation system

- Slam