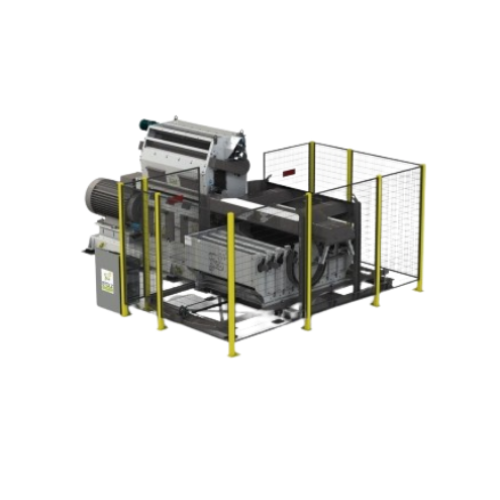

Automatic screen selector for hammermills

Enhance efficiency in your production line with this screen selector, offering seamless automation and precise control to minimize downtime and ensure consistent quality in processing solid, granular, or powdered materials.

Automates Screen Selection for Hammermills

The Self-Standing Screen Selector, known as the SAGA, offered by Stolz, streamlines the screening process in hammermills by automating the selection of screens, thereby reducing manual intervention and downtime. Designed for industries like feedmill, agrofood, and biofuel, it facilitates applications in screening and selection for end-products ranging from animal feed pellets to biofuels like ethanol. With its capability to integrate seamlessly into existing grinding installations, the SAGA utilizes electrically controlled movements for smooth transitions and increased operator safety. By ensuring the traceability of screens and reducing noise exposure, it also contributes significantly to improved working conditions. The SAGA is adaptable to various Stolz RMP type hammermills, making it versatile for different product types, including solids, granules, and powders, providing operational flexibility and enhanced production efficiency.

Benefits

- Minimizes production downtime through automated screen selection, boosting productivity.

- Enhances operational safety by reducing manual handling and exposure to noise.

- Increases production flexibility with adaptable integration into existing setups.

- Ensures traceability of screens, supporting quality assurance measures.

- Promotes energy efficiency with controlled, power-saving movements.

- Applications

- Agrofood, Industrial dedusting, Port silos, Grain silos, Biofuel, Feedmill

- End products

- Palm oil, Port grain storage, Stored wheat, Dust-free flour, Ethanol fuel, Corn storage, Animal feed pellets, Sugarcane bagasse, Breakfast cereal grains, Soybean oil

- Steps before

- Grinding, Raw Material Feeding

- Steps after

- Pelleting, Milling, Mechanical Handling

- Input ingredients

- cereales, flours, mash, cocoa, rice, bulk product

- Output ingredients

- screened materials, processed grains, cleaned ingredients

- Market info

- Stolz is known for its expertise in designing and manufacturing industrial machinery and equipment, particularly for the agricultural sector, including animal feed, grain processing, and bulk materials handling systems. They have a strong reputation for quality and innovation.

- Automation

- Automatic data exchange with production automaton

- Screen sets available

- 2 or 4 sets

- Compatibility

- Adaptable to STOLZ RMP type hammermills

- Space requirement

- Can be placed in existing manual grid exchange installations

- Noise Exposure

- Limited

- Safety

- Increased safety through electrically controlled motion

- Production Downtime

- Limited

- Traceability

- Ensures traceability of screens

- Movement Control

- Electrically controlled smooth movements

- Power saving

- Power saving design

- Automation level

- Automatic

- Changeover time

- Limited downtime

- Traceability

- Screen traceability

- Flexibility

- Production flexibility

- Safety

- Improved working conditions

- Noise control

- Limited noise exposure

- Cereals compatibility

- Yes

- Flours compatibility

- Yes

- Mash compatibility

- Yes

- Cocoa compatibility

- Yes

- Rice compatibility

- Yes

- Biofuel compatibility

- Yes

- Compatibility

- STOLZ RMP type hammermills

- Machine footprint

- Compact, self-standing

- Screen selector type

- Automatic

- Discharge method

- Automatic screen insertion