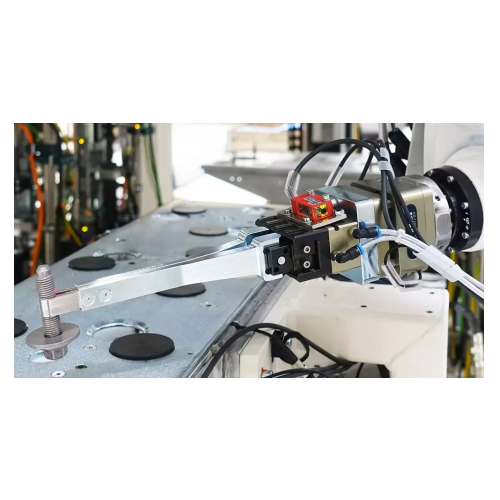

Automatic bolt loading system for automotive assembly

In the automotive manufacturing process, precision and speed are crucial when it comes to assembly operations. Efficient and error-free bolt loading is vital to ensure the integrity and safety of assembled vehicles.

Automates bolt picking and loading operations

The automatic bolt loading system by Dürr is designed to enhance the efficiency of bolting operations in automotive assembly lines. It automatically picks and loads bolts, reducing manual labor and minimizing errors. This system seamlessly integrates into existing assembly processes, ensuring quick and accurate bolt placement. Known for its reliability and precision, the system supports high-volume production environments. Dürr, a leader in production efficiency, provides this innovative solution to help automotive manufacturers streamline their assembly operations, thereby reducing downtime and increasing overall productivity.

Benefits

- Increases assembly line efficiency

- Reduces manual labor and errors

- Seamless integration into existing processes

- Supports high-volume production

- Enhances overall productivity

- Applications

- End products

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Automation level

- High / Fully automated

- Changeover time

- Quick / Minimal

- Cleaning method

- Automated cleaning feature

- Energy efficiency

- Optimized / Enhanced

- Product type compatibility

- Bolt and nut variants